Higher Performance and Consistent Quality

With the systron proHD, SGP now achieves:

-

20–25% higher output on shaped glass

-

significantly reduced manual handling

-

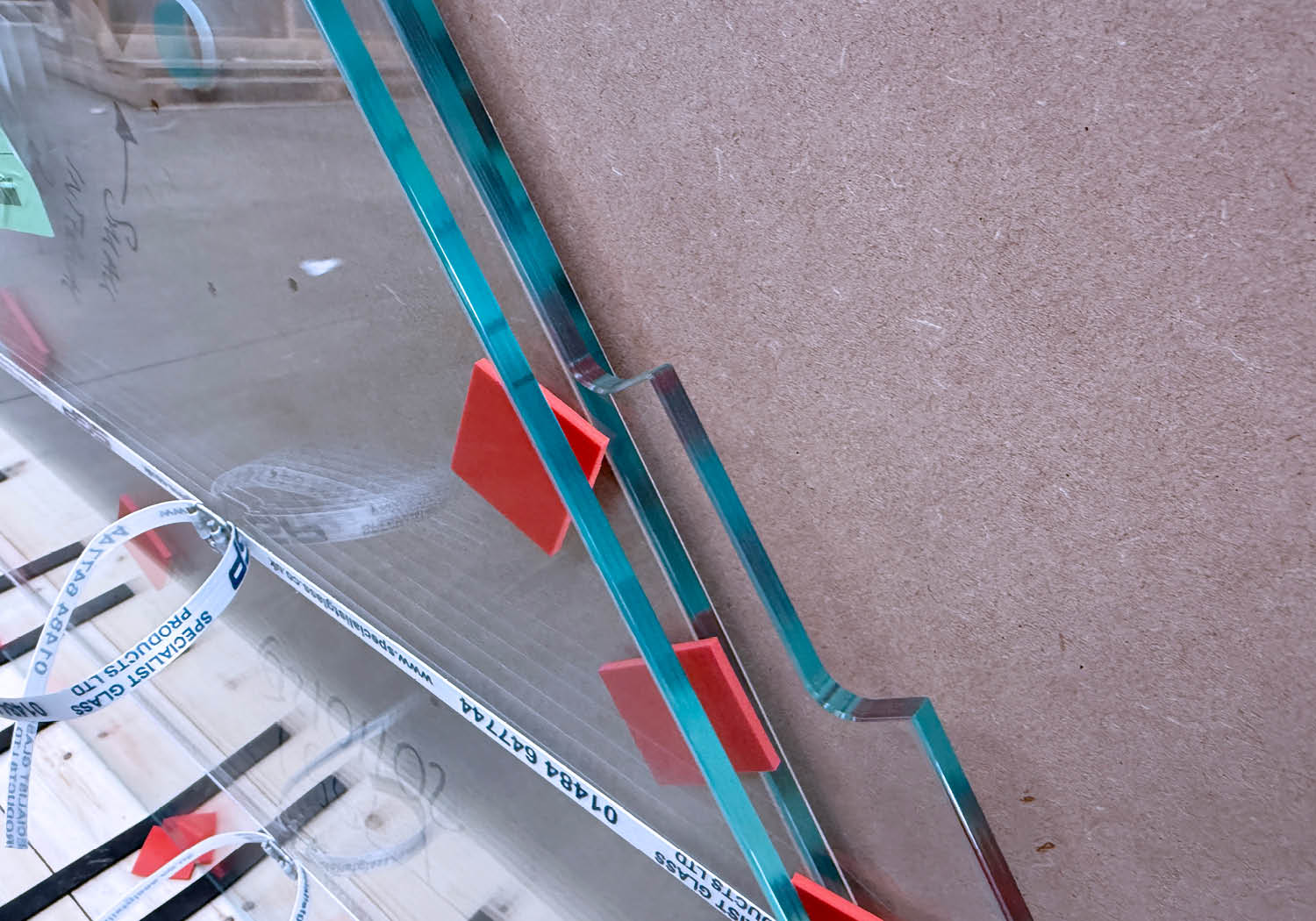

consistent edge quality on coated and laminated glass

For sensitive surfaces, the advantages are especially noticeable. Andrew explains:

“The water cushion technology is a real benefit. The panel is supported without mechanical contact, which minimises the risk of scratches.”

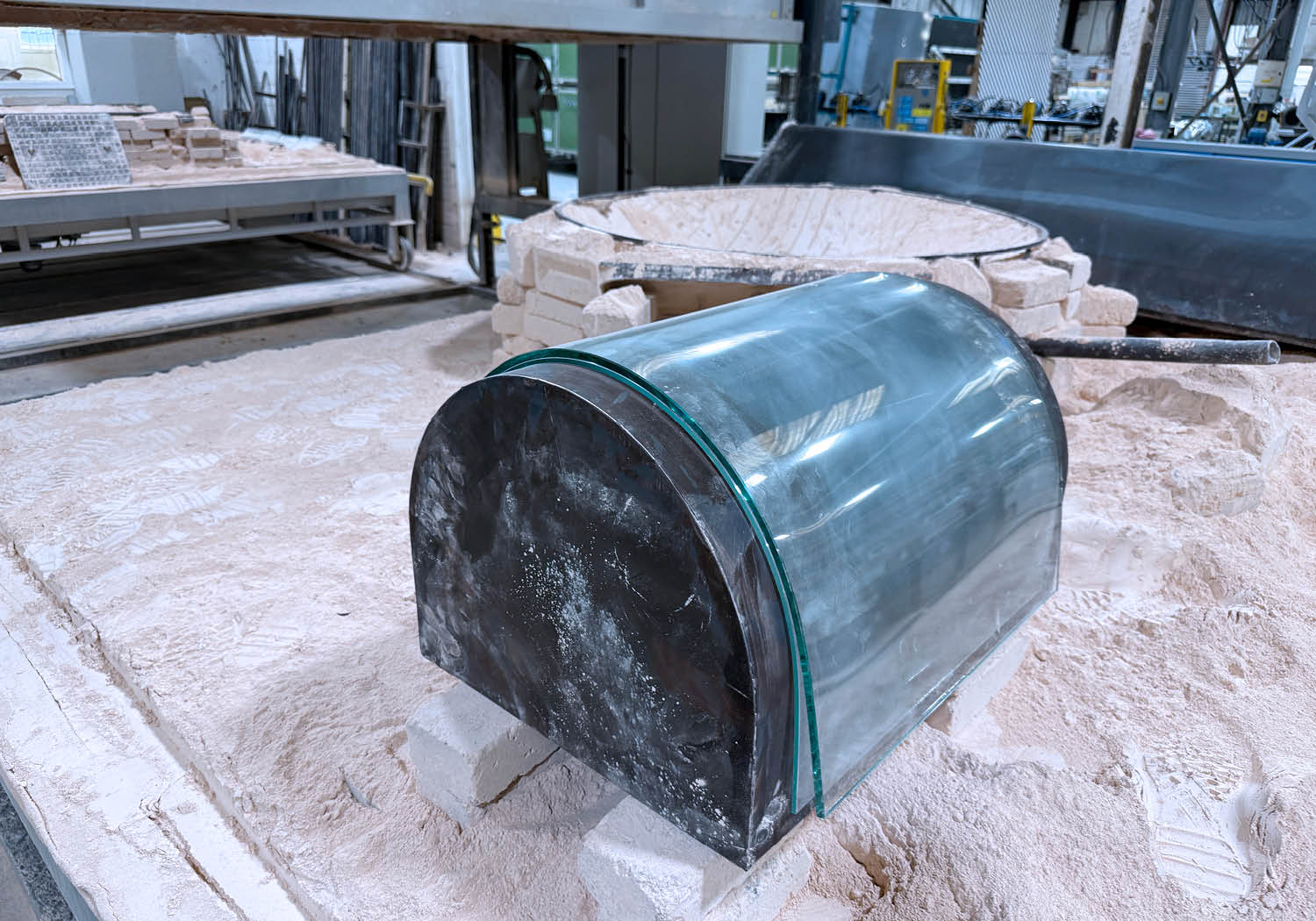

Flexibility Through Integrated Waterjet Cutting

The high-pressure waterjet has become essential for SGP’s production of non-rectangular and bespoke components. Andrew highlights its relevance:

“A large part of our production consists of non-rectangular shapes. The waterjet is ideal because there’s no setup time between shapes. You go straight from a circle to a triangle or a completely free contour.”

The waterjet also impresses with its efficiency: “Often, radii can be cut even faster than rectangular corners.”

Applications range from architectural cut-outs to kitchen splashbacks and openings for sockets and switches. As Andrew notes: “It works precisely, repeatably and cleanly. That’s exactly what we need for our bespoke parts.”

Reliability Secures Short Lead Times

The clear machine concept, good accessibility and reliable remote support significantly reduce maintenance effort. “We haven’t had any serious downtime,” says Andrew Taylor. “And if something does occur, it’s resolved quickly. This stability is crucial for maintaining our tight lead times.”

Many routine tasks are now handled internally, reducing external service requirements and minimising production interruptions.