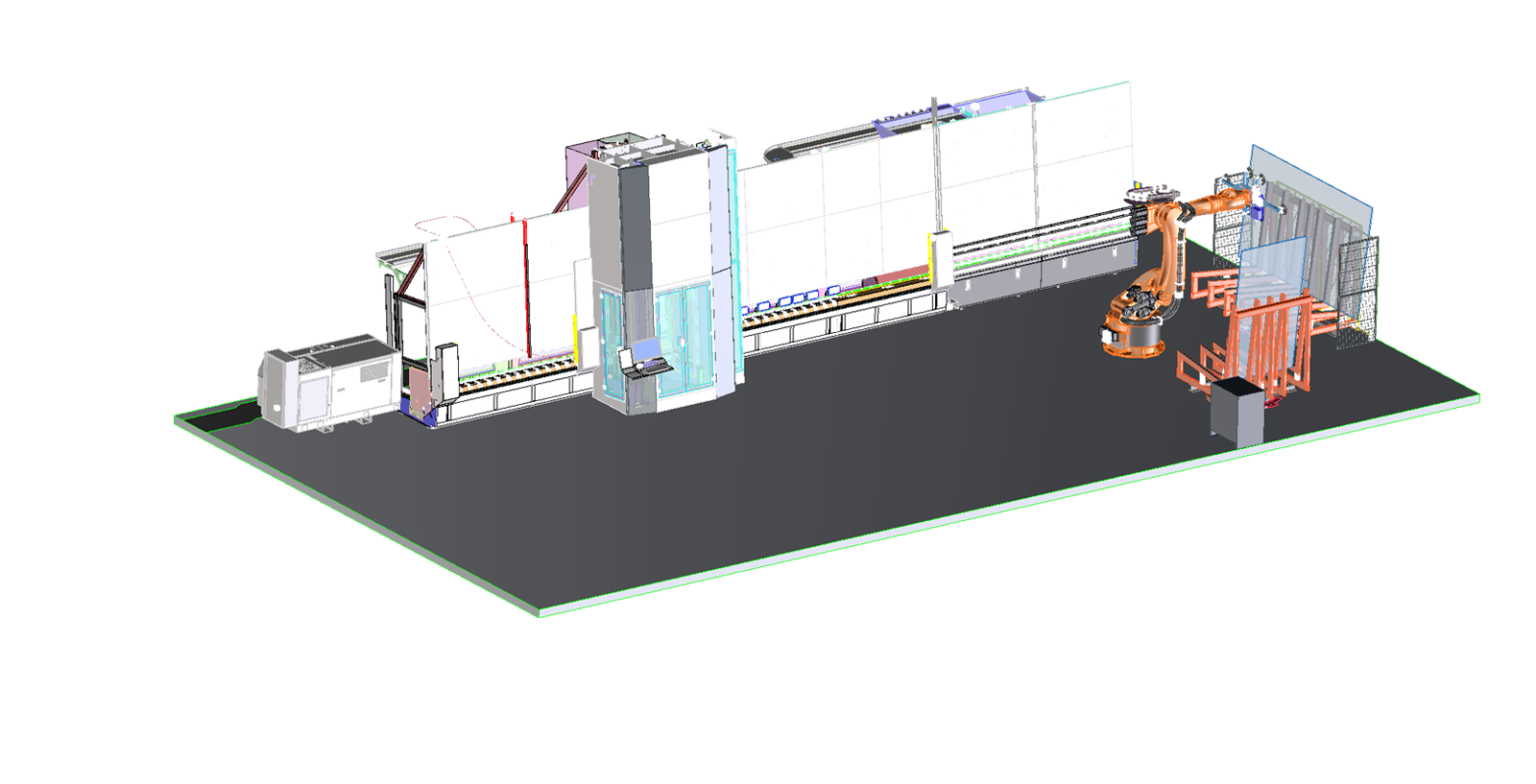

AUTOMATED ROBOT LOADING

Increase the degree of automation of your systron glass processing centre with automatic robot loading. The glass to be processed are loaded using L- or A-racks either on immovable stacking stations or on swiveling stations and placed on the machine by the robot.

With this solution, the machine operator can either manually remove the products after the visual inspection OR a robot can automatically unload the processed panes OR a rack unloading station can be installed to implement a fully automatic loading and unloading process. All systron machines can be supplied and retrofitted with the automatic L-rack solution.

The automatic robot loading is sized according to customer requirements. The maximum dimensions and the maximum glass weight depend on the selected systron processing centre as well as the robot size.