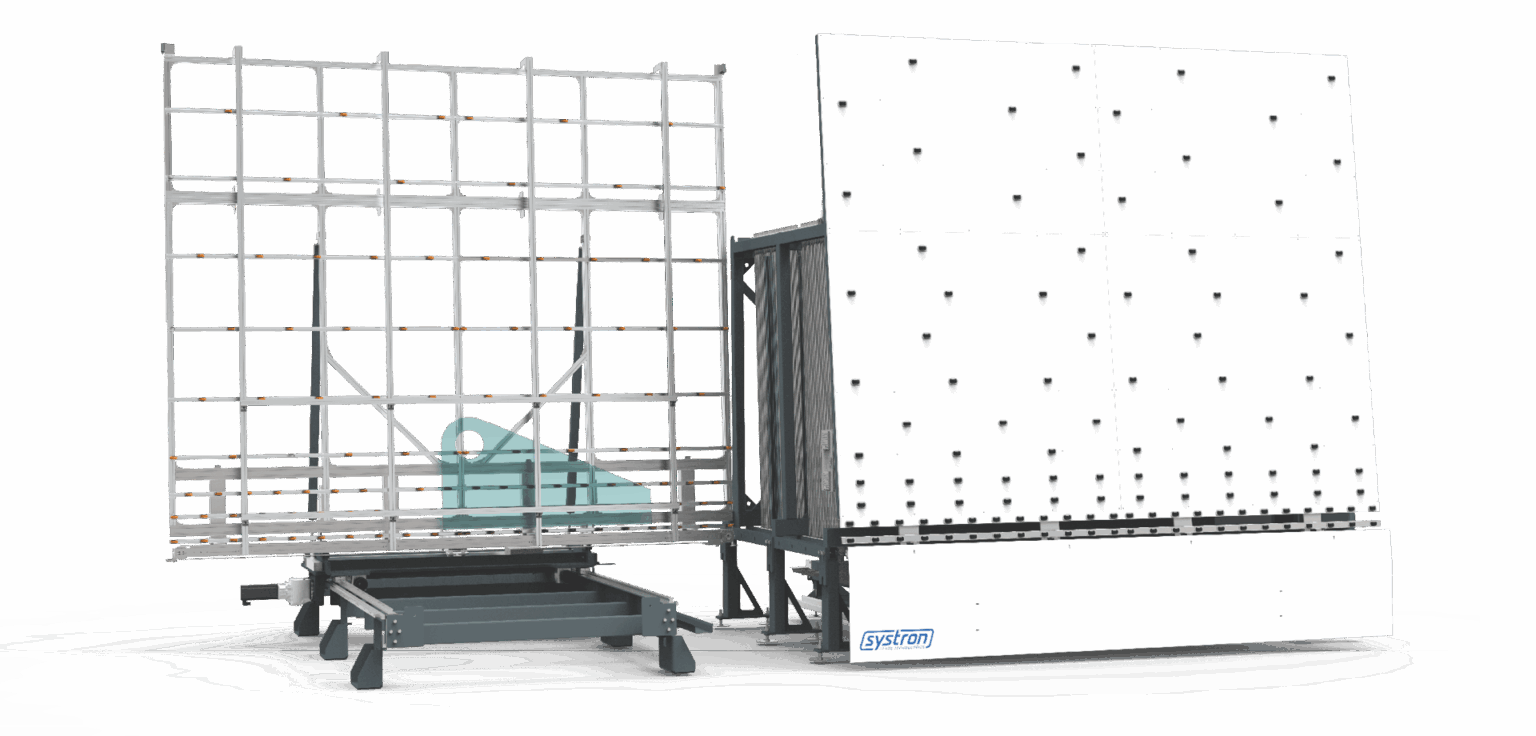

Automated Storage Solution

The automated storage solution ensures efficient buffering and a continuous material flow within the glass processing line.

Glass sheets are transferred fully automatically between the storage system and the glass processing centre – both on the infeed and outfeed side.

A shuttle connects the processing unit with the fixed storage rack, enabling seamless loading and automatic buffering after processing.

An integrated sorting function within the outfeed storage system automatically sorts the glass sheets based on freely definable criteria – for example, by size, thickness, job number, or next processing step.

The system is ideal for customers using transport trolleys from different manufacturers as their internal logistics system.

SMART BUFFERING & SORTING – SMOOTH GLASS FLOW:

- Optimized buffering between processing stations – for continuous line operation, 25% higher capacity and up to 8 hours of autonomous runtime

- Seamless integration with portal or robot loading for fully automated processes

- Automatic sorting of glass sheets by definable criteria to optimize production flow and simplify complex order structures

- Reduction of internal transport trolleys – more usable production space

All systron processing centres can be equipped or retrofitted with the automated storage solution – ensuring efficient processes with minimal personnel effort.