Initial situation grinding with esX

The grinding result can be adjusted using the processing tool (usually diamond tool), the feed rate and the contact pressure.

To date, the Seaming/Grinding process on the esX was only possible in one cycle.

Following processes have been possible:

0 = Transport to the Washing Machine

1 = Seaming/Arrising: The machine uses the seaming/arrising recipe

2 = Grinding: The machine uses the grinding recipe

In the recipe – the settings for each glass thickness – the following parameters are set to obtain a seamed or ground edge:

- Feed speeds

- Contact pressure

Depending on these parameters and the grit of the tool, the amount of material removed (removal rate) is determined.

New function for more flexibility

A new process was developed. Thanks to a software update, it is now possible to process the glass in several passes.

Possibility 1:

Two cycles with the same tool. This means that the removal rate doubles and the industrially ground edge is more likely achieved.

Possibility 2:

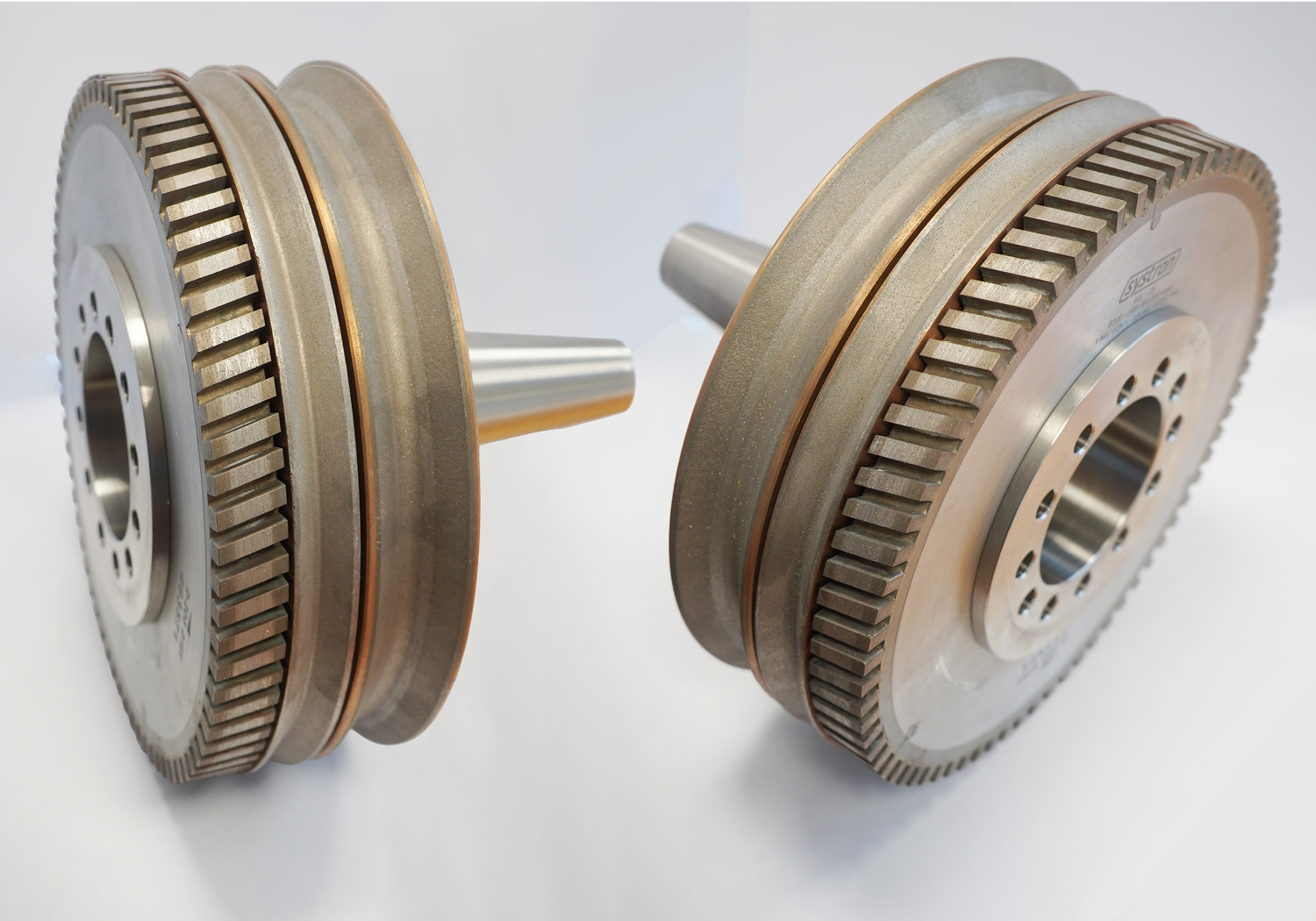

Pre-grinding with a coarse tool (oscillating, flat-segmented tool) and subsequent seaming using a V-tool.

Beautiful results for industrially ground edges.

Following processes are now possible:

0 = Transport to the washing machine (without processing)

1 = Seaming/Arrising: The machine uses the seaming/arrising recipe

2 = Grinding: The machine uses the grinding recipe

3 = Grinding & Seaming: Recipe for removal and arris for 1st and 2nd round (2 cycles with autamatic tool change)

As before, also in this process, the grinding head follows the glass contour due to the floating tool spindle. The removal rate is determined by feed rate, contact pressure and tool grit.

“With the automated combination of an oscillating and a V-tool, you have the ability of arrising and industrially grinding glasses from 4-12 or 10-19mm without changing tools,” explains systron CEO Franz Schachner.