His expectations for the new CNC processing centre were clearly defined: “Above all, increasing the capacity and the grinding, polishing and cutting speed, as well as the system availability, were my focus.” So they decided to purchase a systron proHD glassprocessing centre with integrated waterjet.

“The sophisticated waterjet technology is a real plus, because it guarantees top quality cuts and contours,” says Breu.

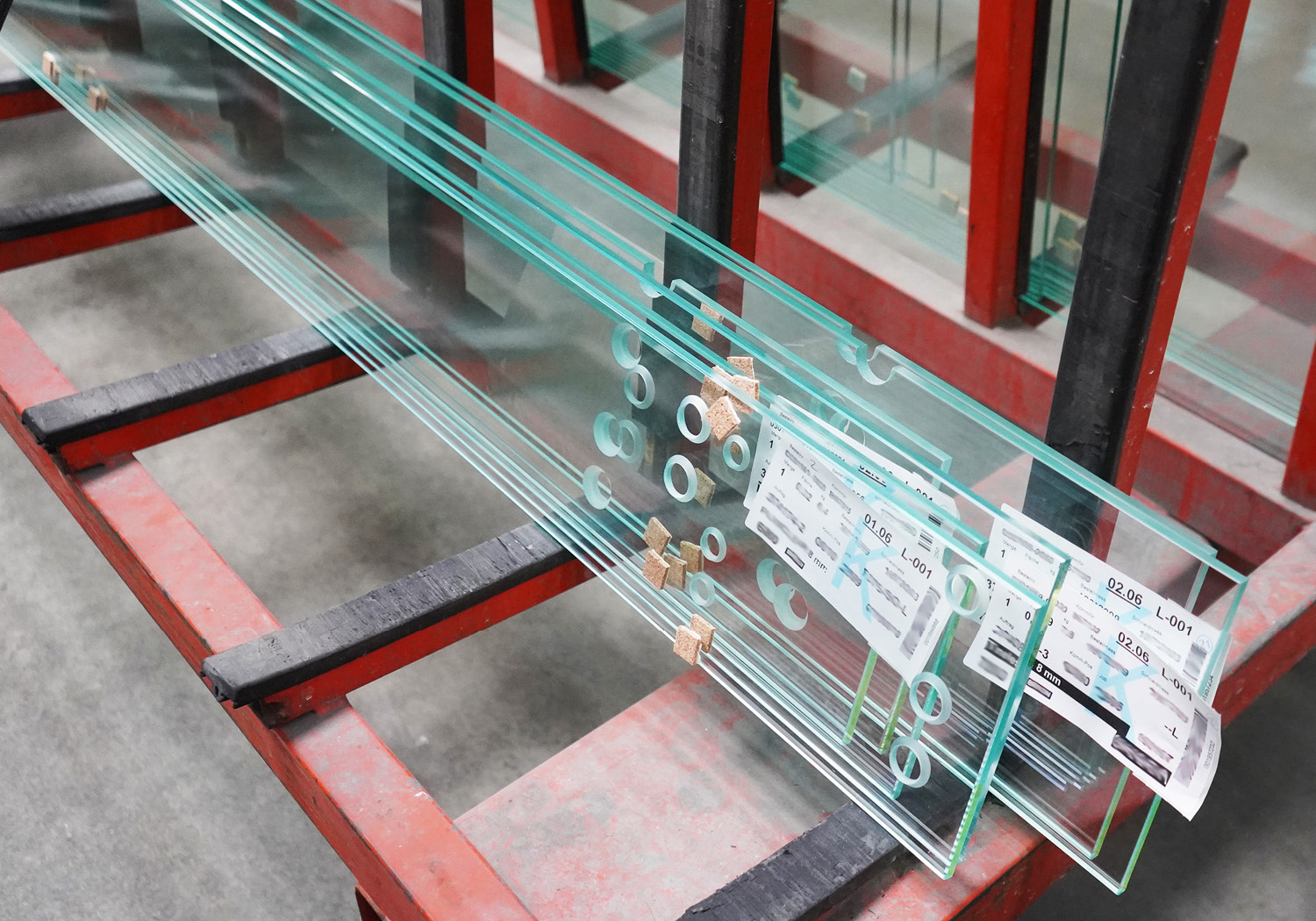

Up to 4000 bar pure water power cut inner- and outer contours with the most complex geometrics with the highest precision. These contours can be toughened without post-processing, reducing the production time considerably. There are no limitations caused to the need for cutting tools and the maintenance costs are minimal. Breu also mentions the perfectly integrated systron water purification system: “Clean water is essential for the final quality of the glass. We use the systron system in connection with our central water treatment, which increases the cleaning interval to around 1x / month – another increase of efficiency.”