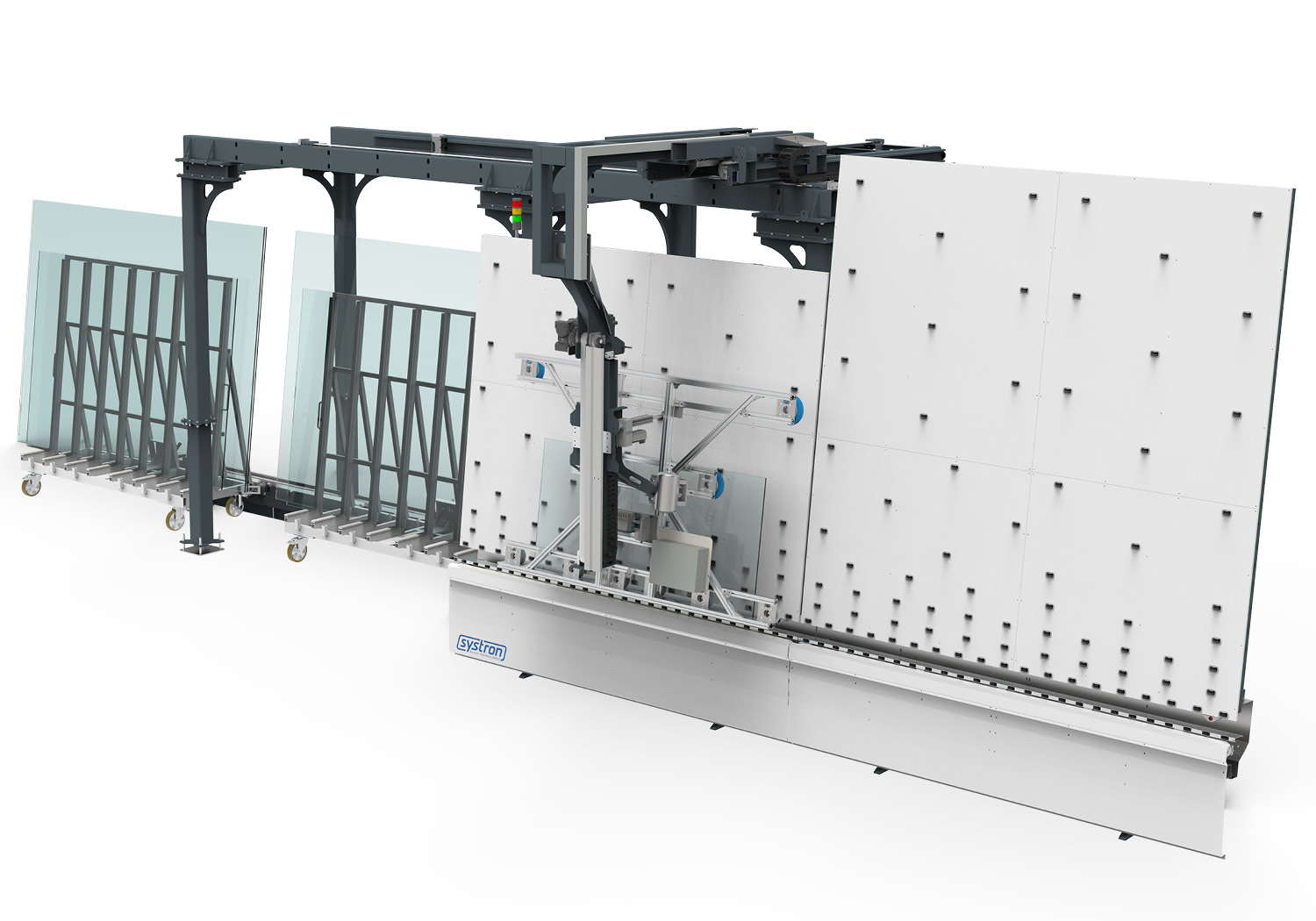

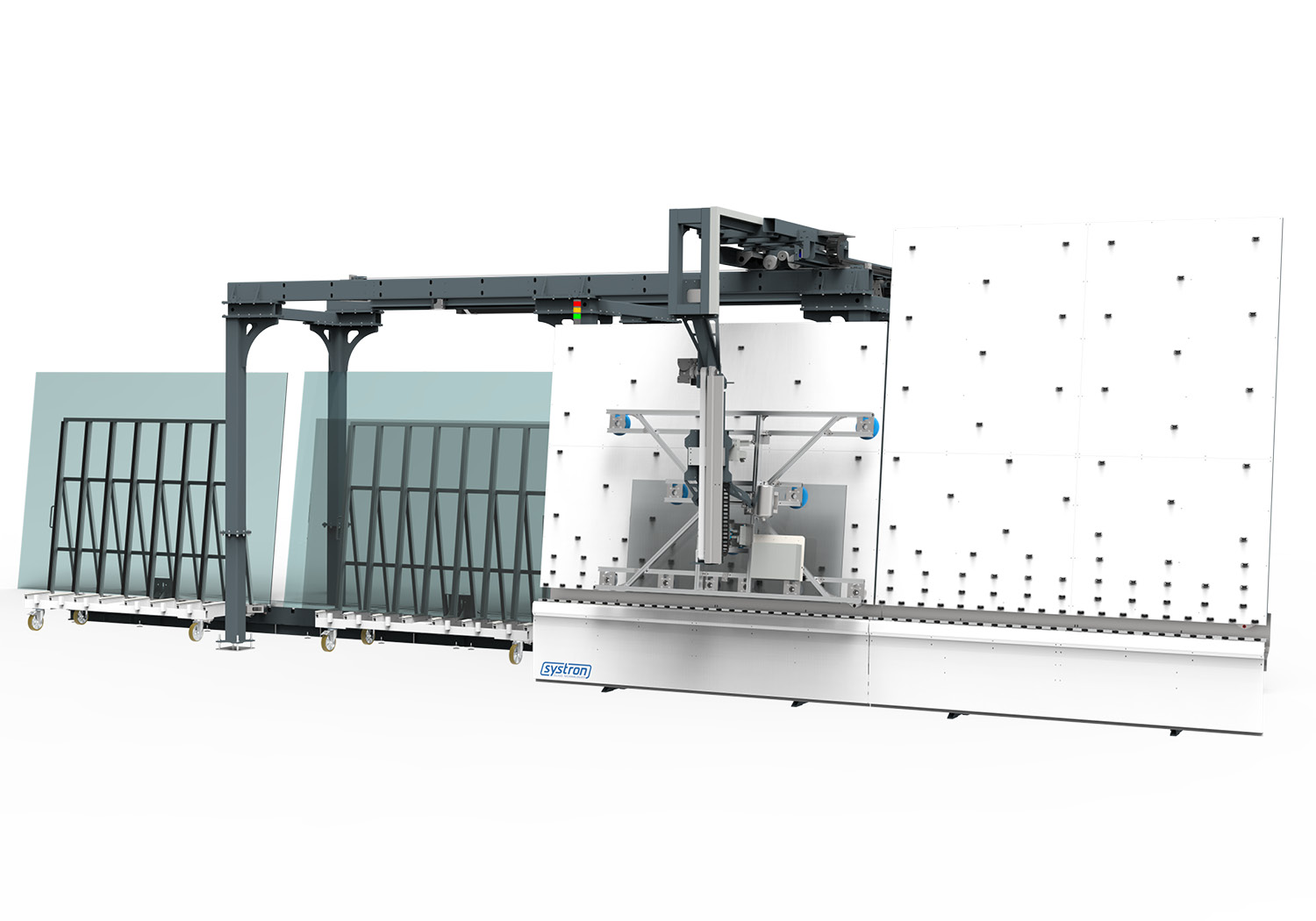

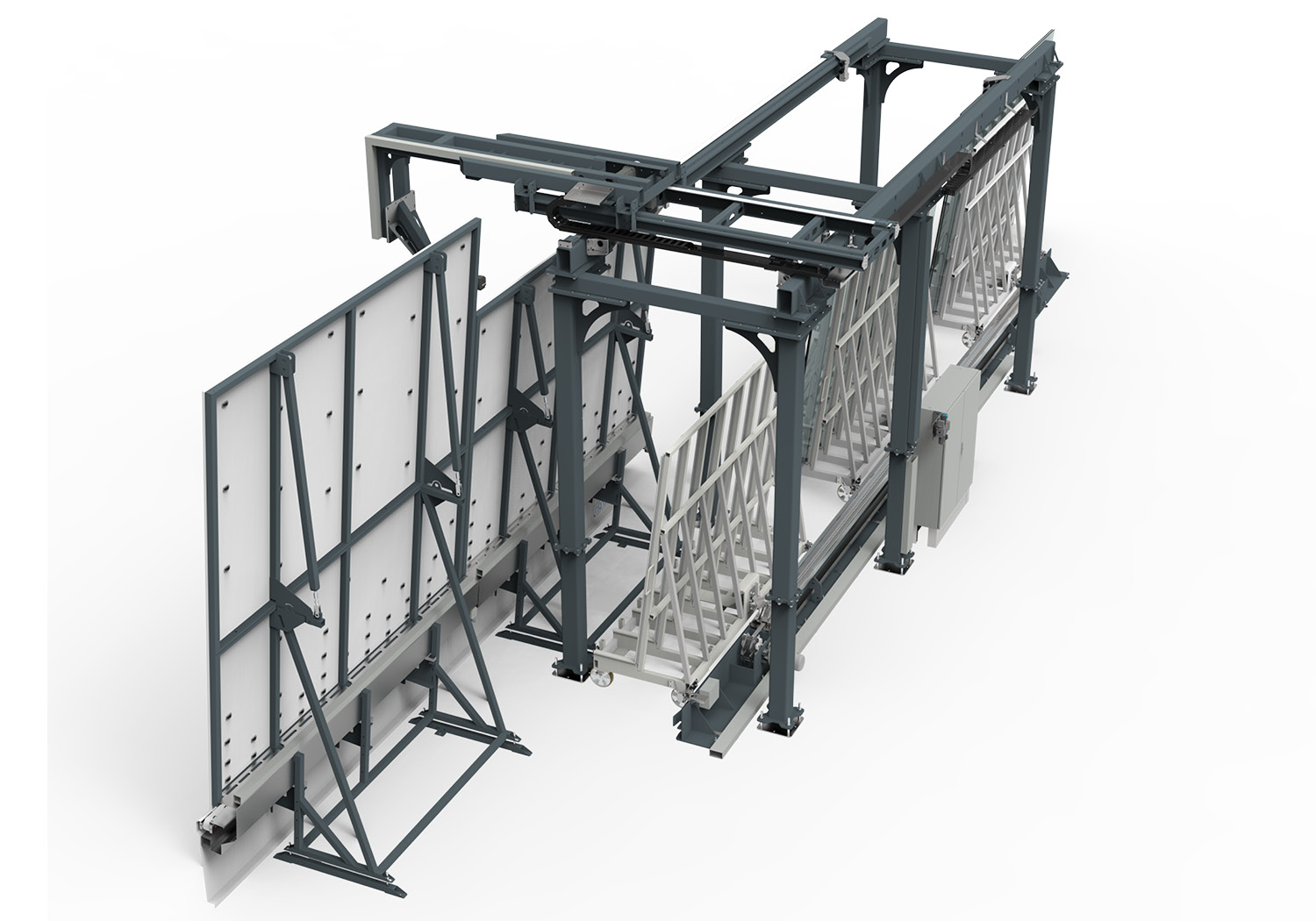

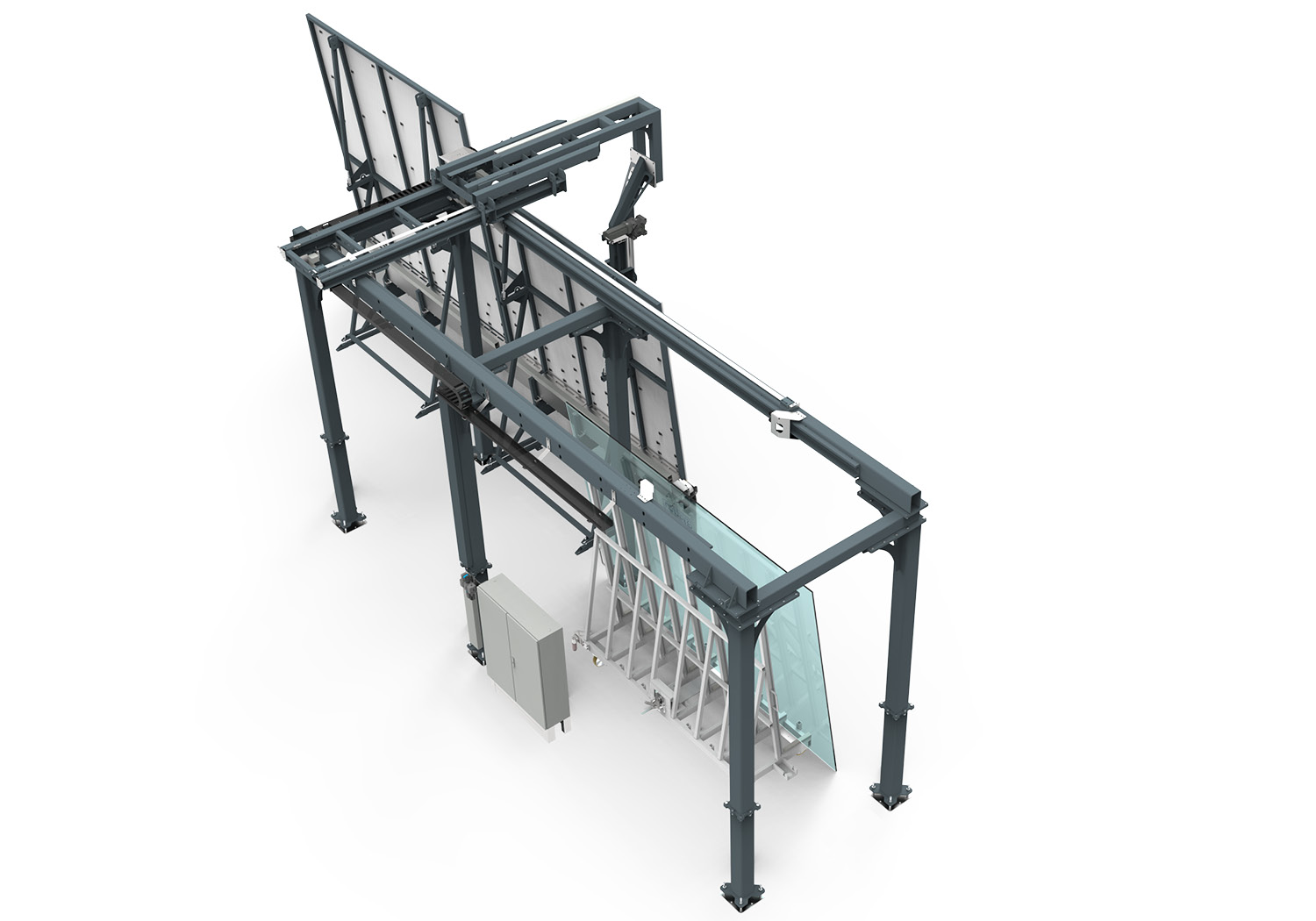

Portal Loading System – The Smart Alternative to Robotic Loading

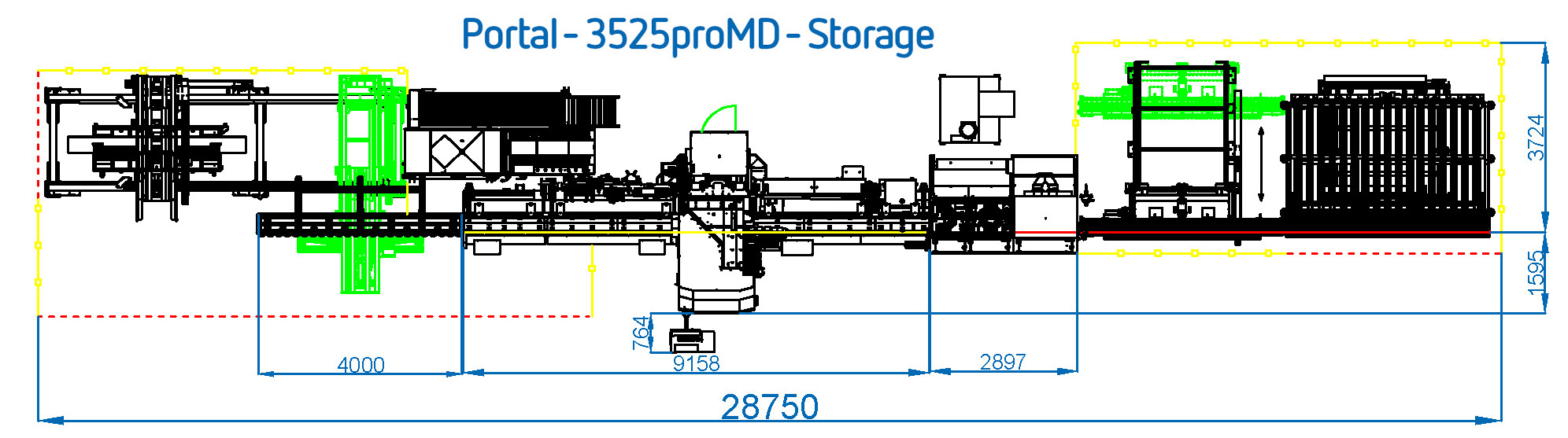

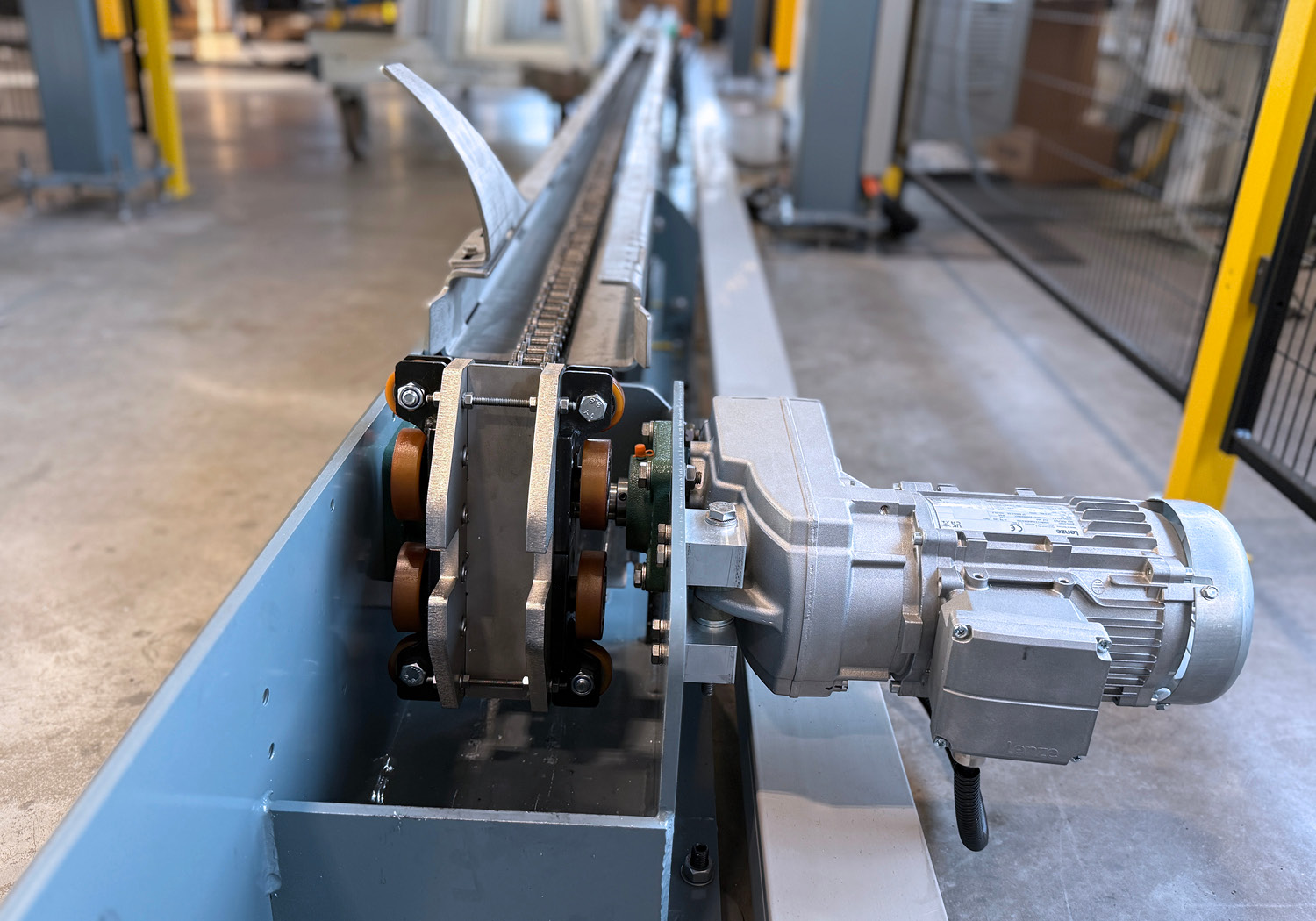

The new systron portal loading system offers a simple, robust, and economical solution for automating glass loading. It has been specifically designed for unloading glass from L-racks and loading a systron processing line – all with a manageable investment.

Compared to complex robotic systems, portal loading convinces with straightforward functionality, reliable technology, and easy operation. The system is also highly flexible: it can safely handle both standard rectangular formats and custom special shapes.