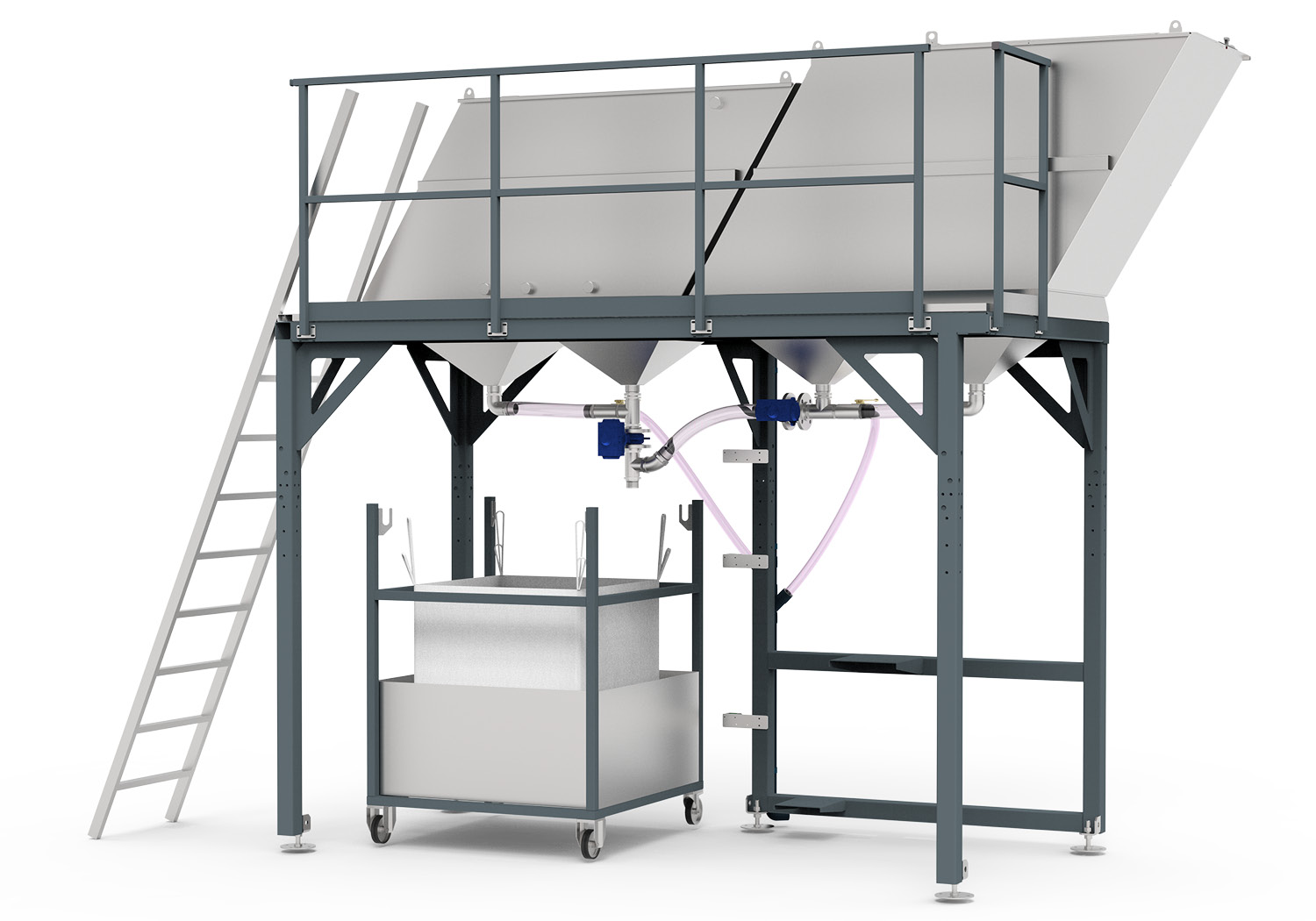

1. Waste-Water Intake & Flocculant Dosing

Process water from the glass processing centre is pumped into the waste-water tank from multiple sources:

• machine basin

• manual basin suction

• Big Bag station

• sludge destroyer

A flocculant dosing pump adds the correct amount of flocculant, binding suspended solids and enabling rapid settling — the foundation for efficient lamella clarification.

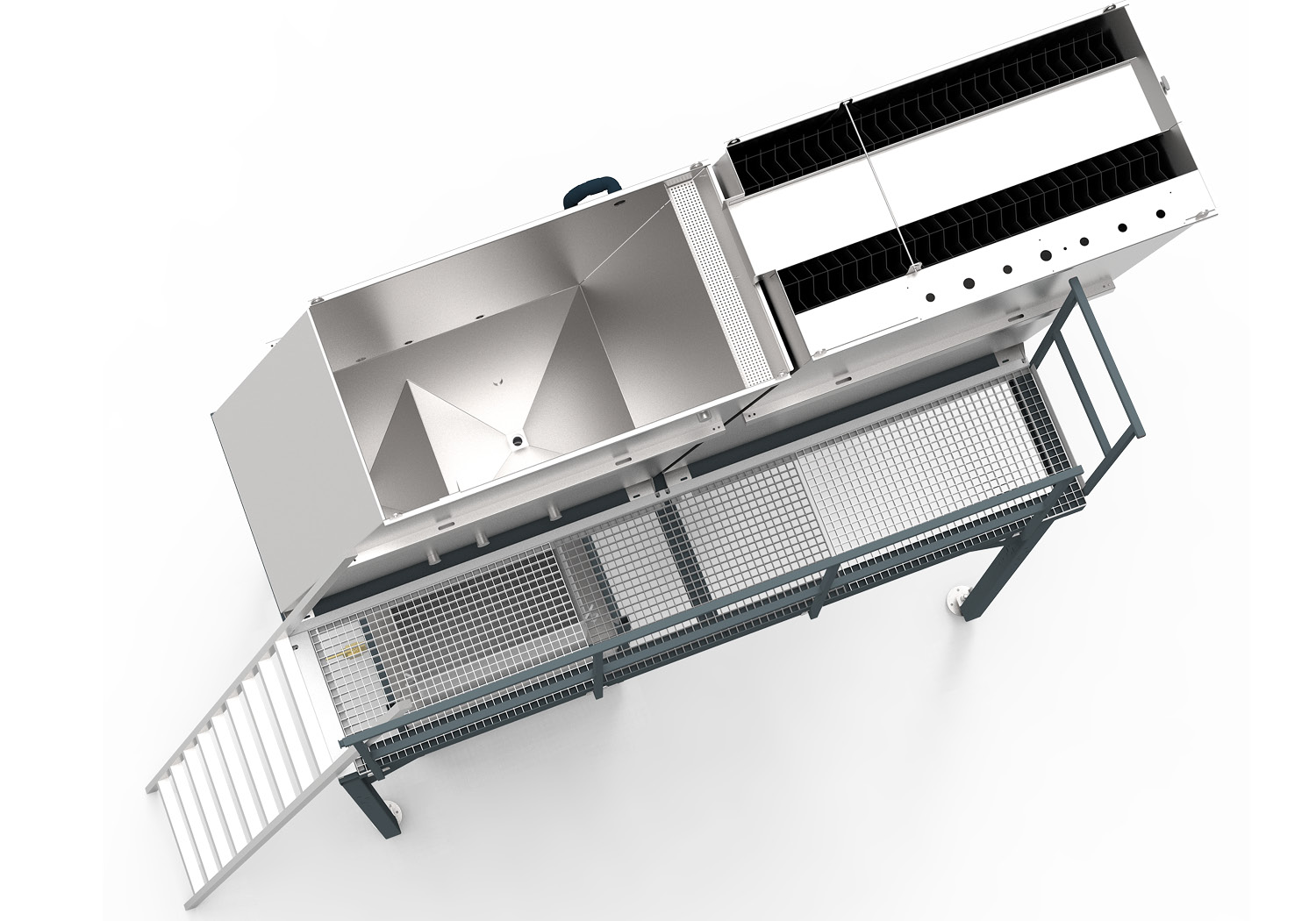

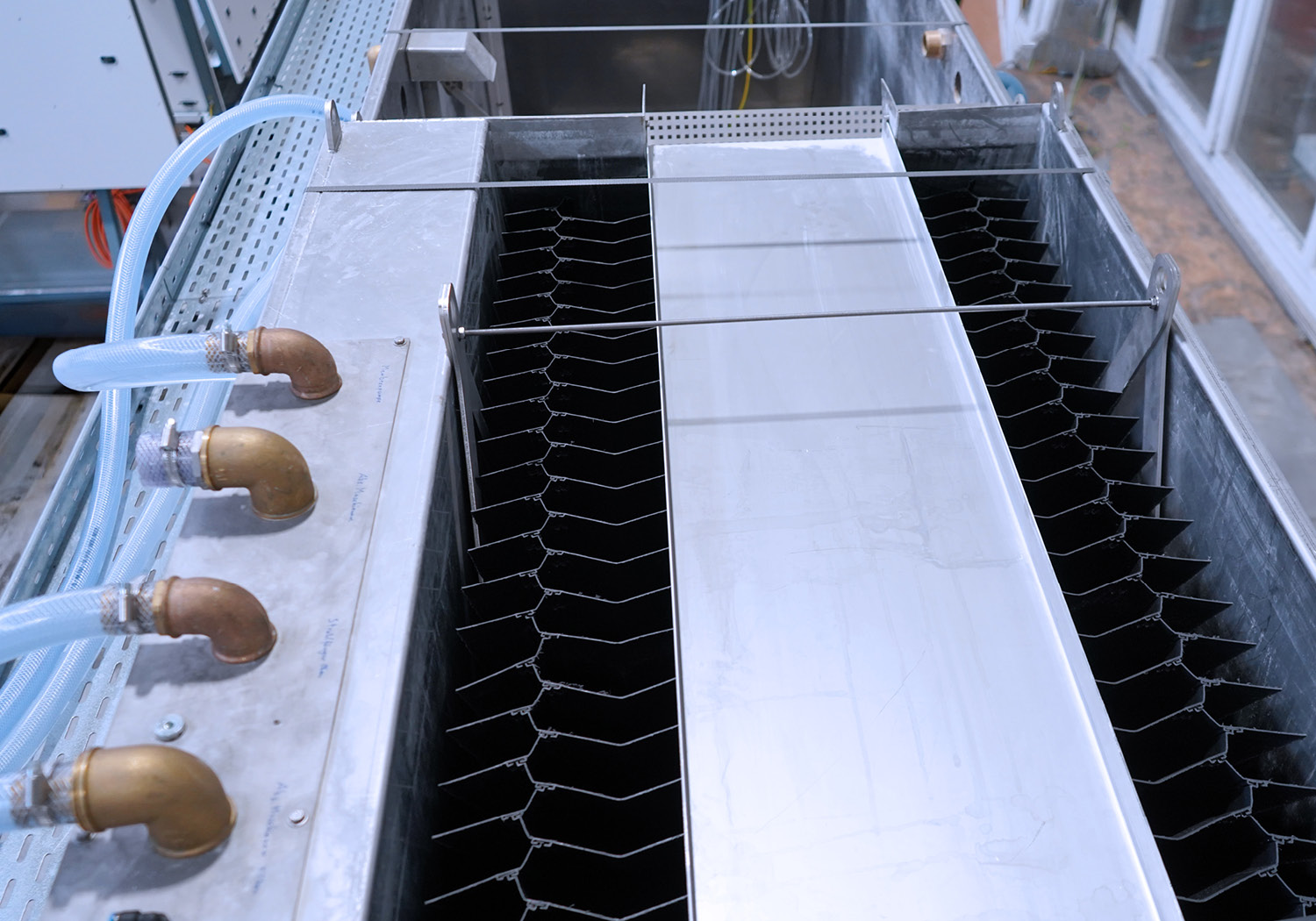

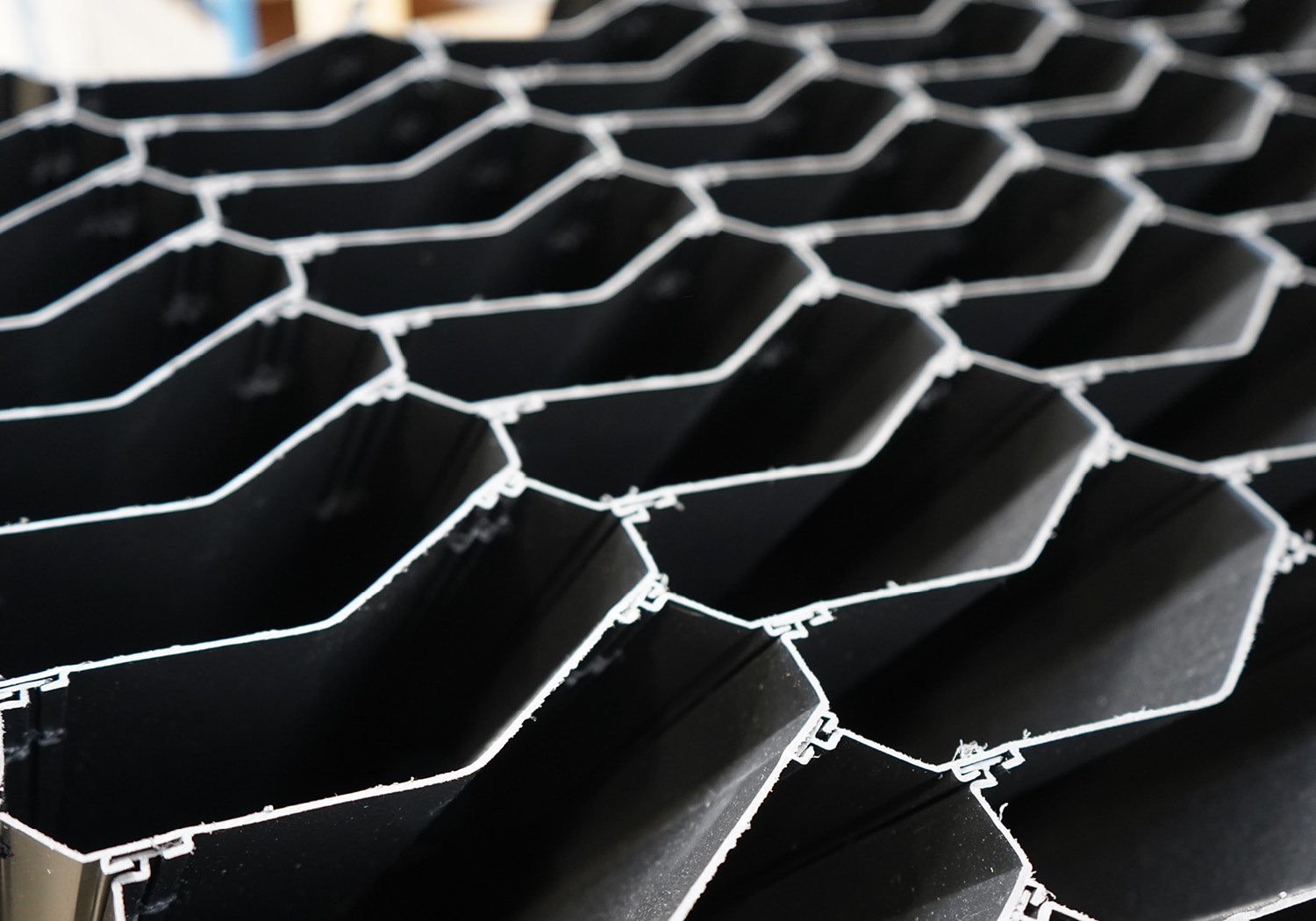

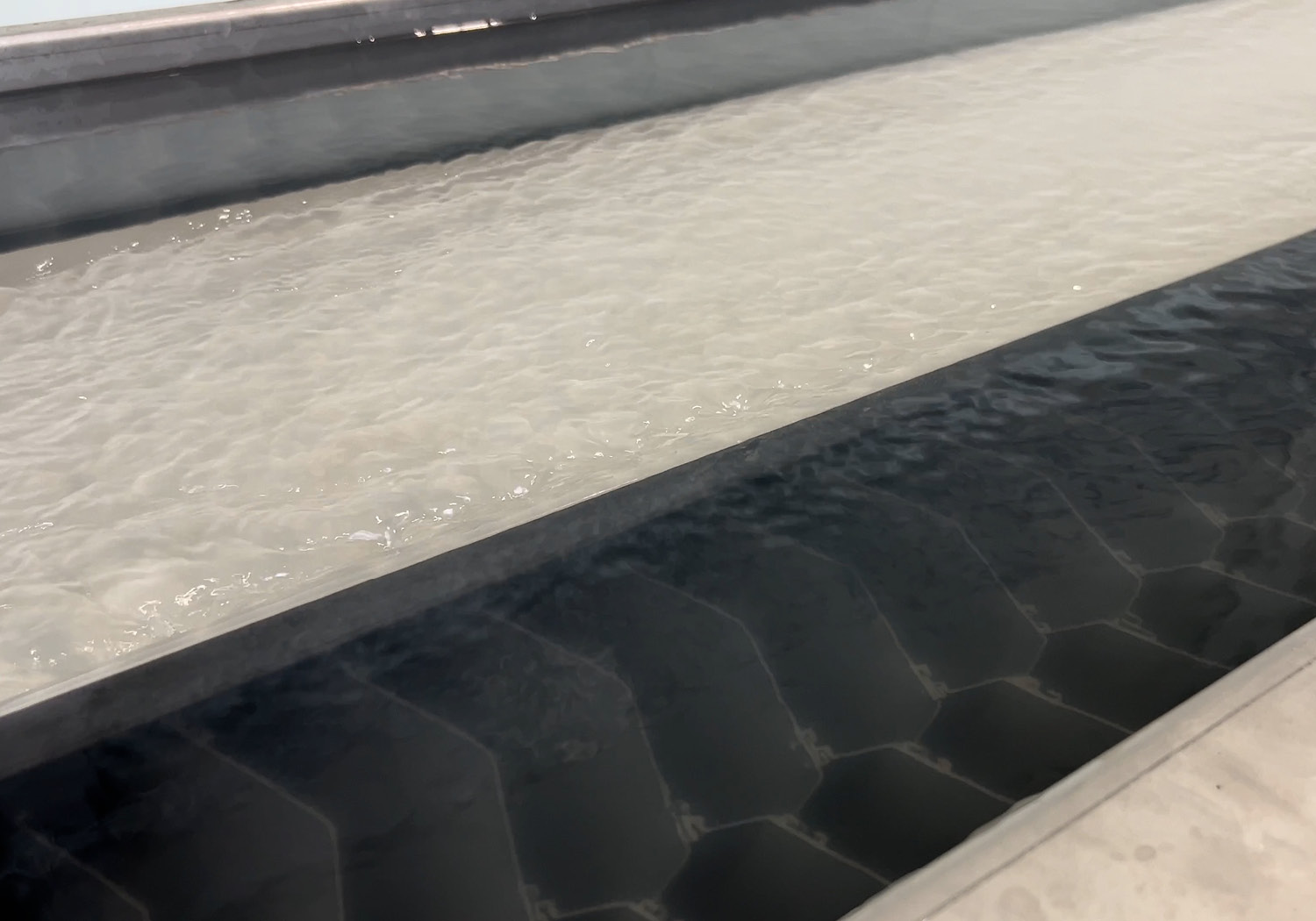

2. Lamella Clarifier with Honeycomb Plates

At the heart of the SWR300 is the lamella plate clarifier, a passive filtration system using a proven honeycomb plate structure.

Inside the clarifier:

• The flocculated particles settle on the lamella plates

• Cleaned water rises above the plate pack

• The purified water flows through an overflow channel into the fresh-water tank

The lamella modules are tool-free to remove and replace, making maintenance extremely simple. Replacement is only necessary when plates become fully clogged with sediment.

3. Automated Sediment Removal with Conical Tank Bottom & Big Bag System

The waste-water tank is welded in a conical hopper design, concentrating sediment at the lowest point. Via timed flushing, the sediment is automatically transferred into the Big Bag system.

The Big Bag fulfils two essential functions:

• final filtration stage for residual fine particles

• storage container for cutting sand, glass dust, and PVB residues

Mounted on rollers, the Big Bag trolley allows quick removal and replacement using standard lifting equipment.

4. Return Flow of Filtered Process Water

After passing through the Big Bag filtration stage, the cleaned water is collected in the Big Bag basin and then pumped back into the process water loop.

This ensures stable water circulation, low water consumption and consistent filtration performance.