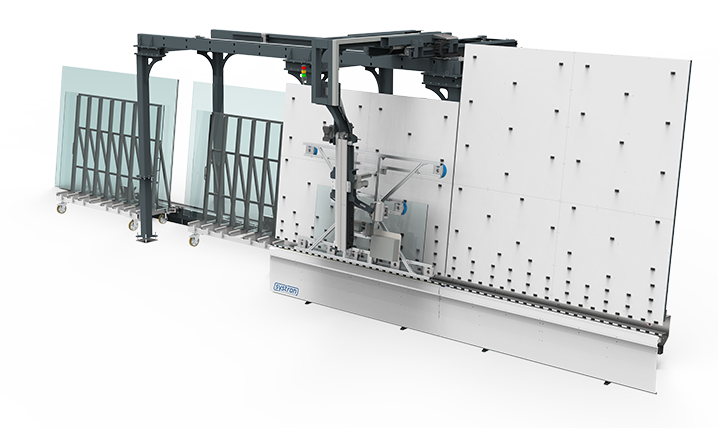

Automated Portal Loading

The portal system features four precisely controlled axes and a total height of 4500 mm.

It is designed for glass sizes up to 3500 × 2500 mm (maximum) and 600 × 200 mm (minimum), specifically developed for unloading glass from L-rack trolleys and loading it into a systron processing centre.

The cycle time for handling glass in the maximum format is less than one minute – measured from picking up one pane to the next (depends on glass thickness).

Loading Specifications:

Loading height: 520 or 780 mm (glass transport line height of the subsequent main machine)

Safety:

The system is equipped with integrated safety devices to ensure safe and reliable operation, particularly during automated loading and unloading.