Rakvåg Glass AS: Transforming Glass Production with Strategic Investments

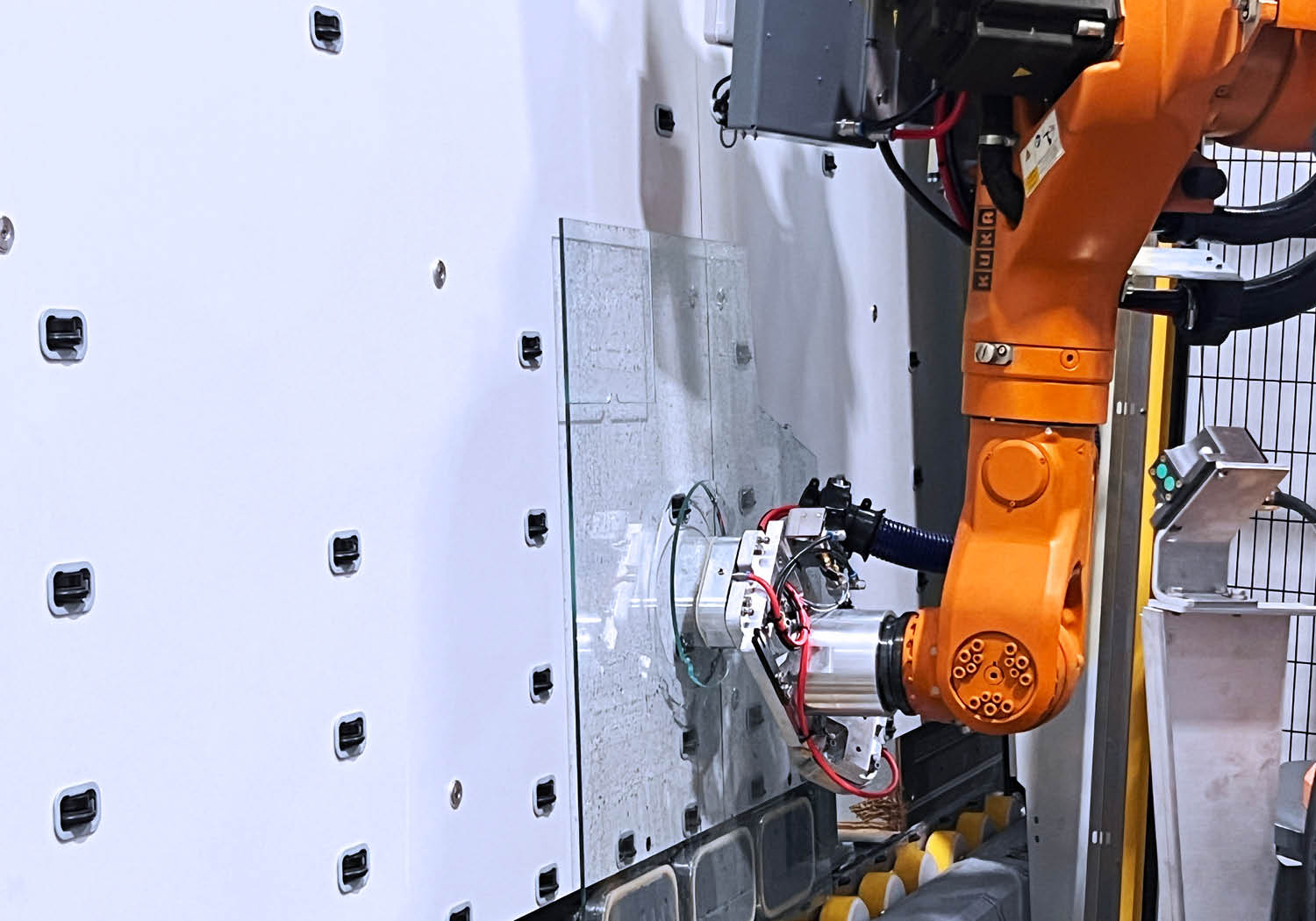

In recent years, Rakvåg Glass AS has secured a strong foothold in the future of glass production through impressive investments and modernizations. With the new fully automated processing centre systron proHD, the company is meeting the increasing demands of a fiercely competitive market. “We are facing increasing competition and preparing the company for the future,” explains Owner and Managing Director Roy Rakvåg.