World’s Leader Saint-Gobain Chose a systron Seaming Machine

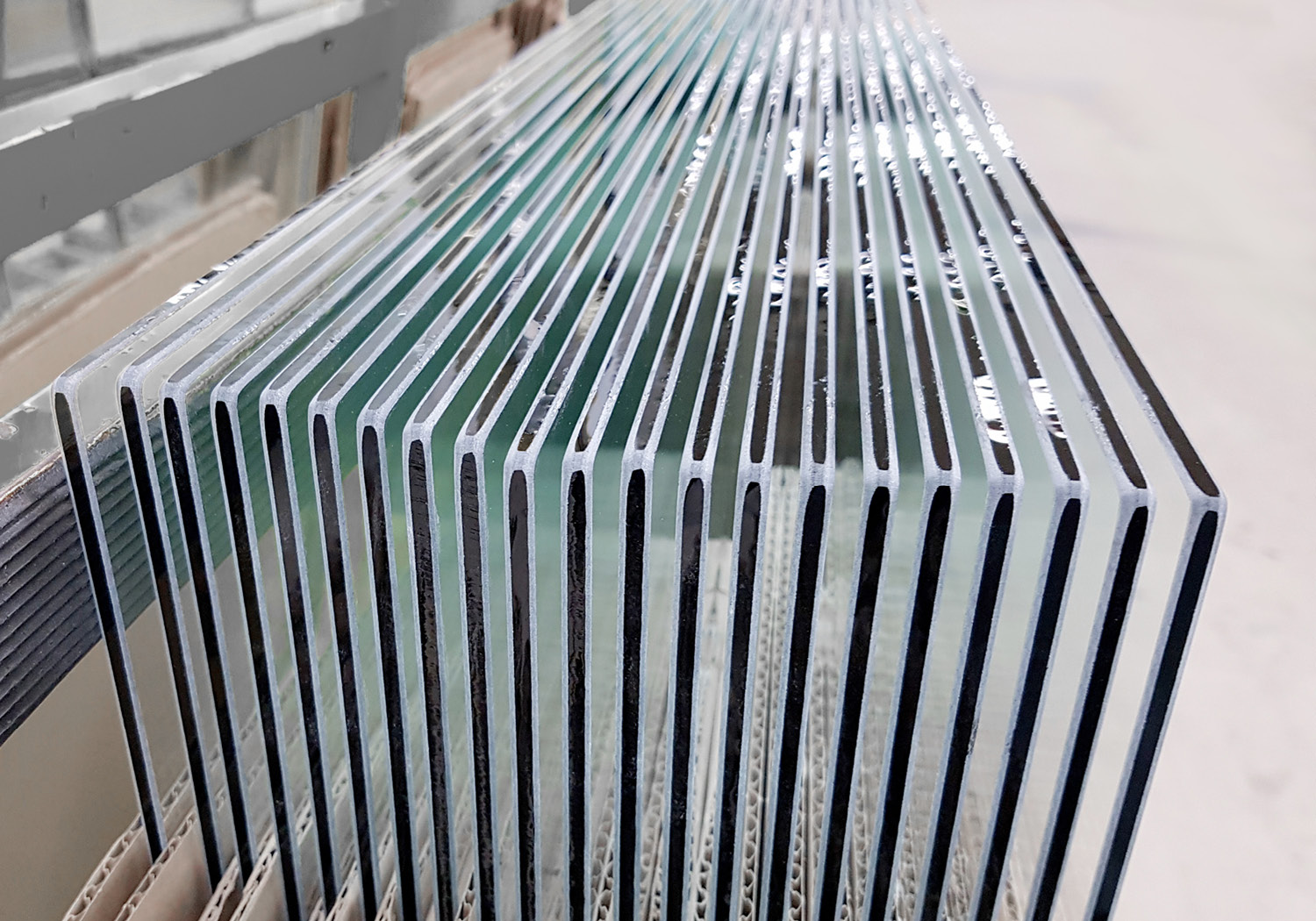

The Saint-Gobain Group has already almost 30 years of history in Poland and belongs to the biggest foreign investors. As for today The Group is represented in our country by 25 production plants with more than 7000 employees and turnover over 1 billion euro. Apart Saint-Gobain the other brands represented by us are, among others, Isover, Rigips, Weber, Swisspacer and Glassolutions – under this brand the company is producing and processing glass in 7 locations in Poland (Lubartow, Szczecin, Barczewo, Poznan, Namyslow, Pruszkow and Jaroszowiec).