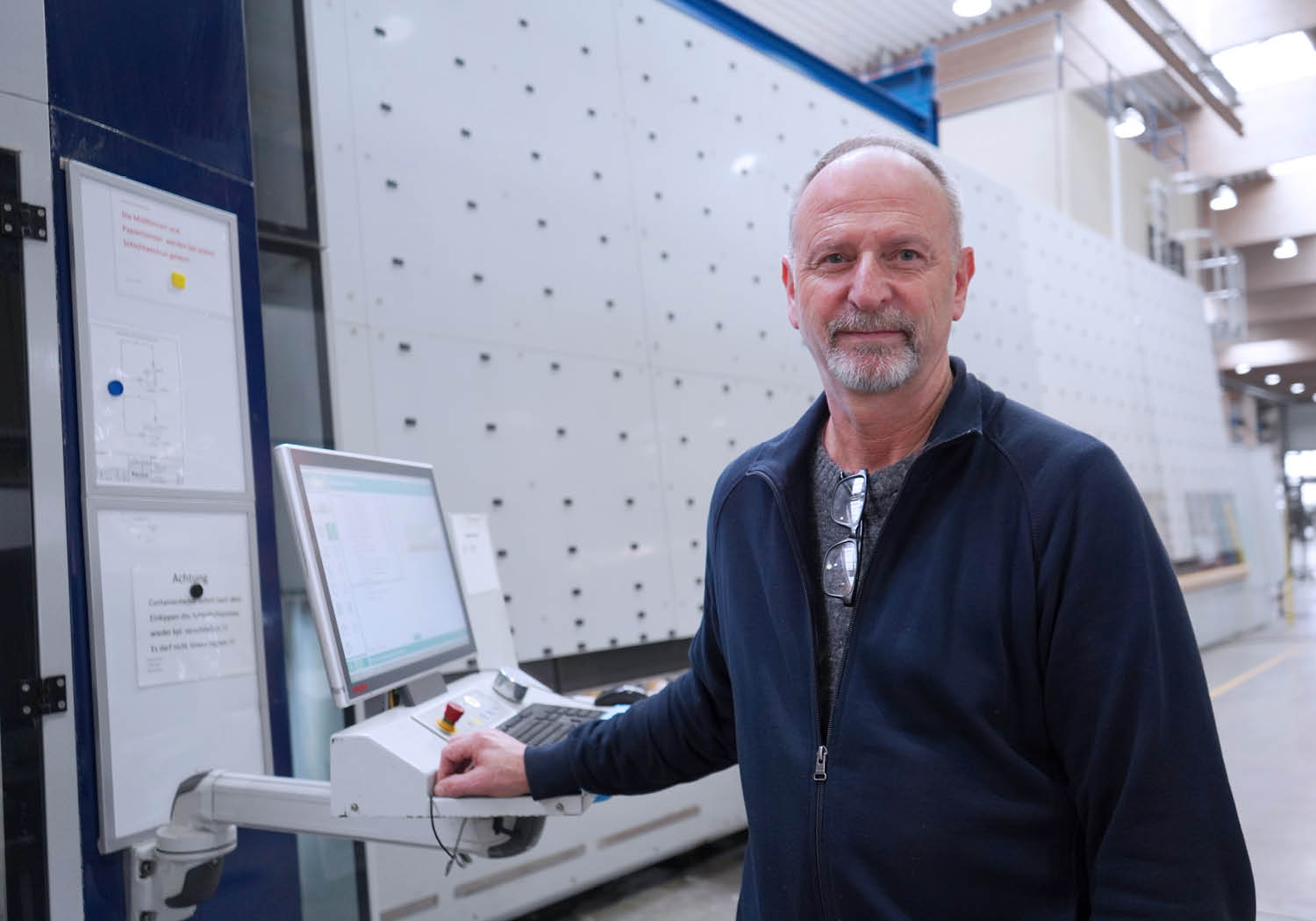

“We examined the vertical proHD glass processing centre for the first time at Glas Gasperlmair in Wagrain in 2015. We were on site when the second systron machine was being set up,” remembers Johann Knogl, who has been working in the glass industry since 1988.

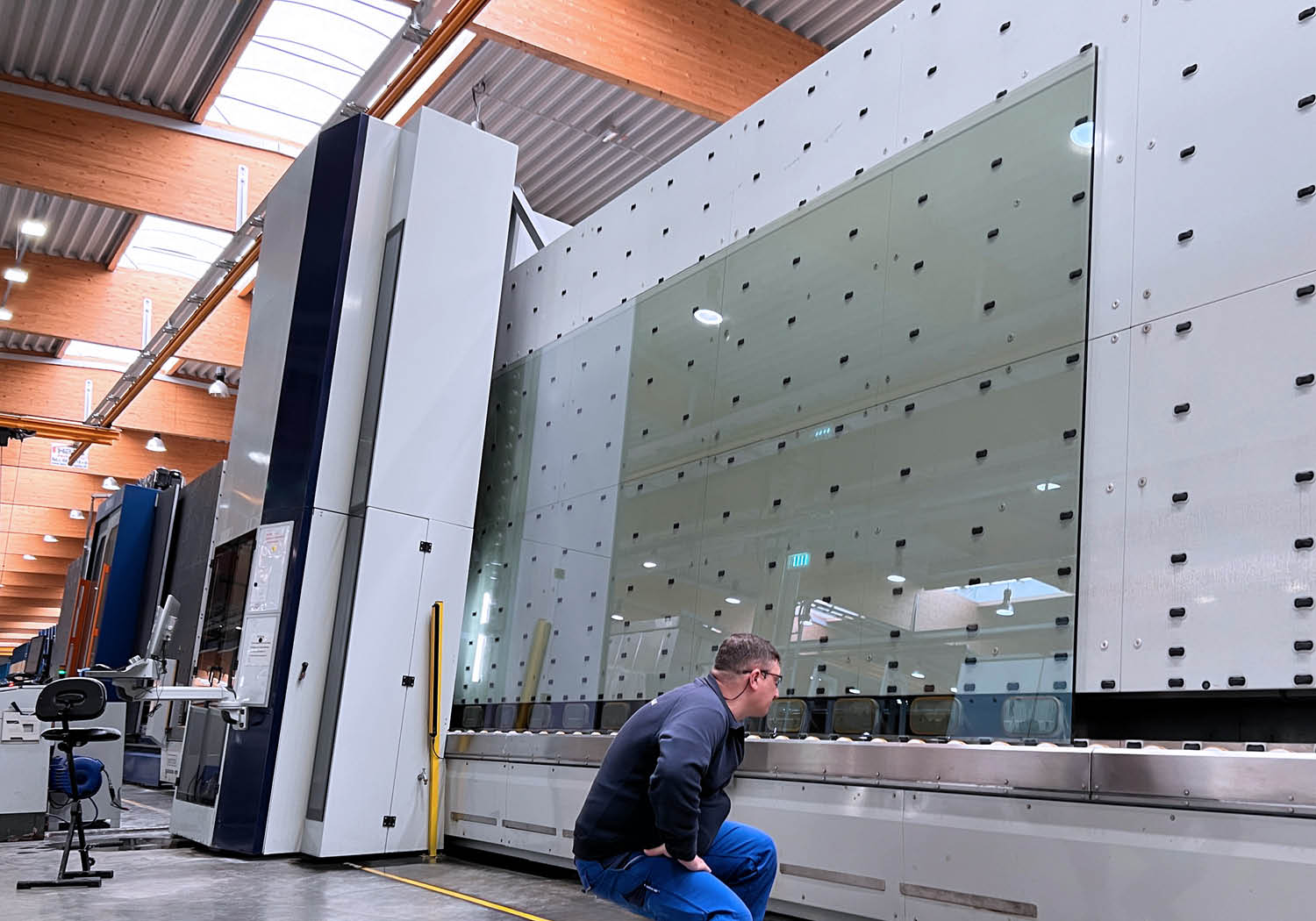

“When I saw it, I thought it was such a gigantic machine, it’s got Caterpillar parts from the crawler tracks. The vacuum suction cups are extremely stable.

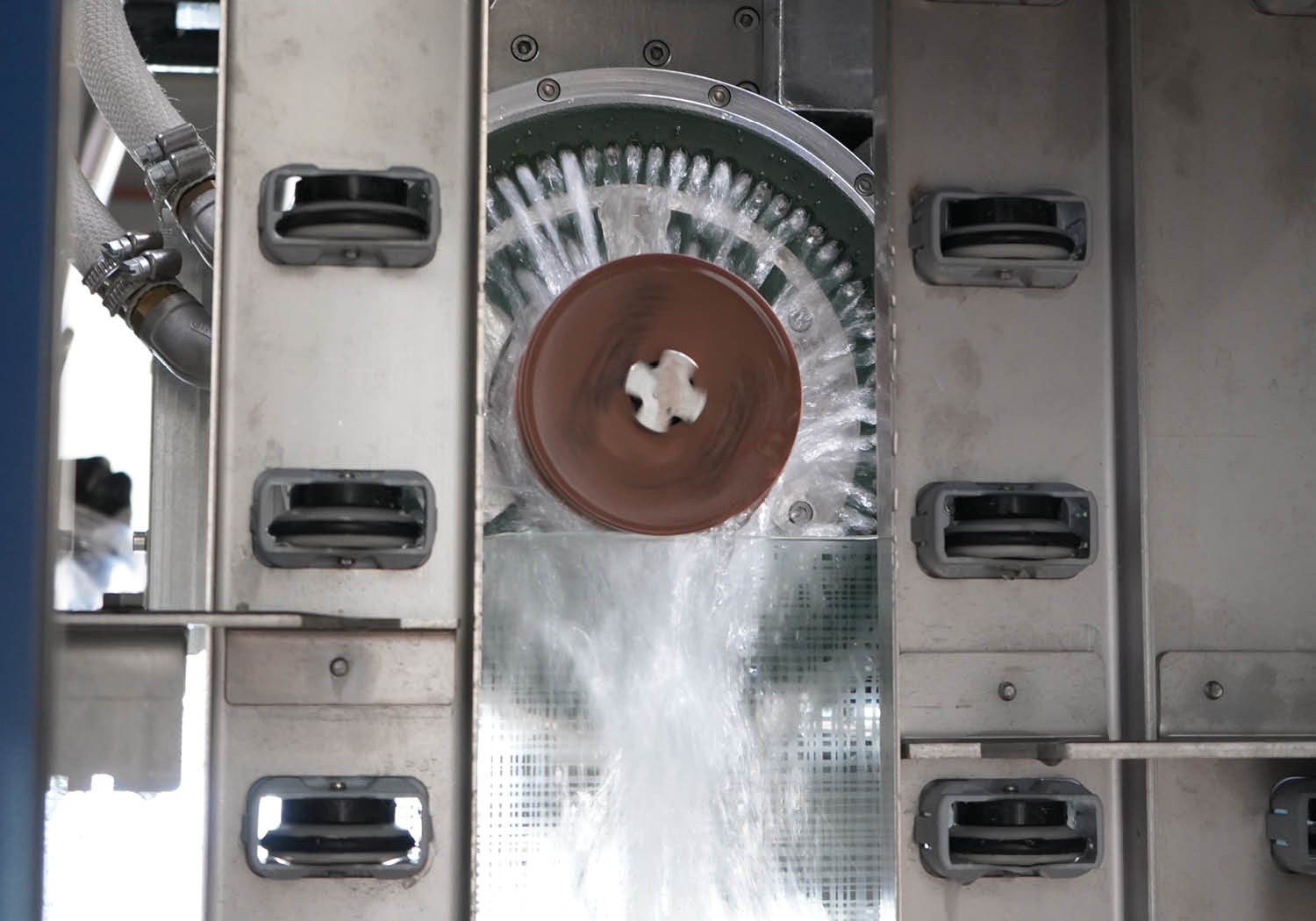

Today the glass guidance is one of the cornerstones of a grinding machine. If you cannot position and hold the glass fully reliably, you will get an incorrect grinding pattern or a poor result. I also liked the grand accessibility of the processing tower, you can get into the machine, which is ideal for cleaning, maintenance or service.” Until then, the systron processing machine was only available with a water jet, the “systron proHD”. Cut-outs are hardly necessary for the architectural business, which is why the glass processing centre was adapted for Interpane and a systron pro Grinding and Polishing Machine was developed for maximum dimensions of 3,300 x 6,000 mm, which was installed beginning Q4 2016.