systron LOOP: Innovative Combination of Cup Wheel Quality and CNC Flexibility

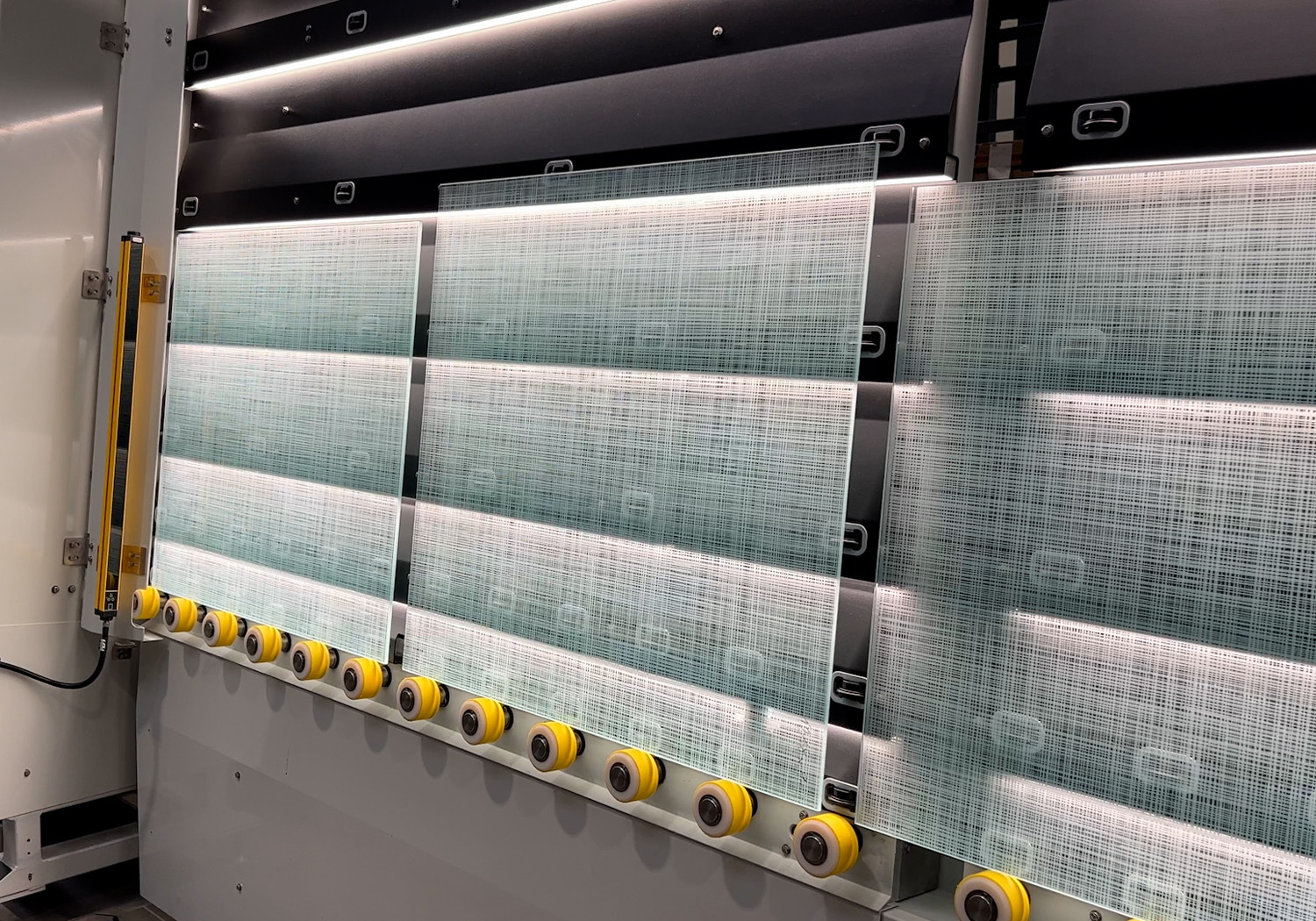

A System for Precise & Fast Glass Processing

“The development of our systron LOOP system for brilliant cup wheel polish was significantly driven by the collaboration with Thiele Glas. The goal was to create a vertical glass processing line capable of producing glass with precise dimensions and angles—even for linear custom shapes—while achieving cup wheel polishing quality. This combination of precise grinding and complex CNC processing in a single system offers numerous possibilities for the glass industry,” explains systron CEO Franz Schachner.

It not only allows the processing of rectangular glass sheets with the highest quality but also the production of typical CNC glass with complex shapes and interior processing. When combined with the systron proHD processing centre, various requirements can be met through a continuous, efficient process.