Rethought and Refined: The new systron storage system with intelligent sorting function

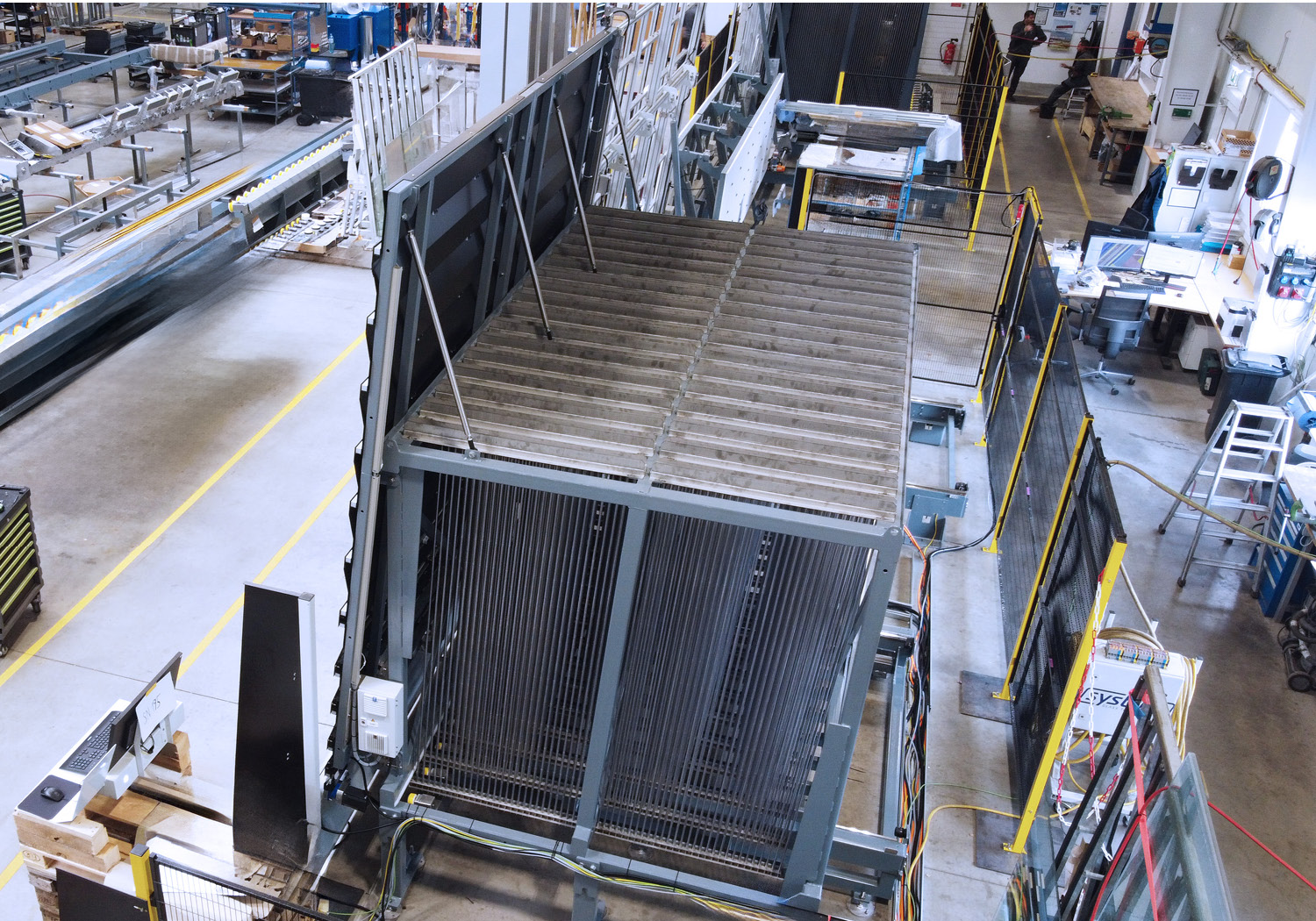

More capacity, larger glass formats, a shorter overall design – and now with automatic sorting:

With the new generation of the systron storage system, the development team has taken an established automation solution to the next level.

The proven system no longer just buffers glass automatically – it now actively organizes the entire material flow within the glass processing line.

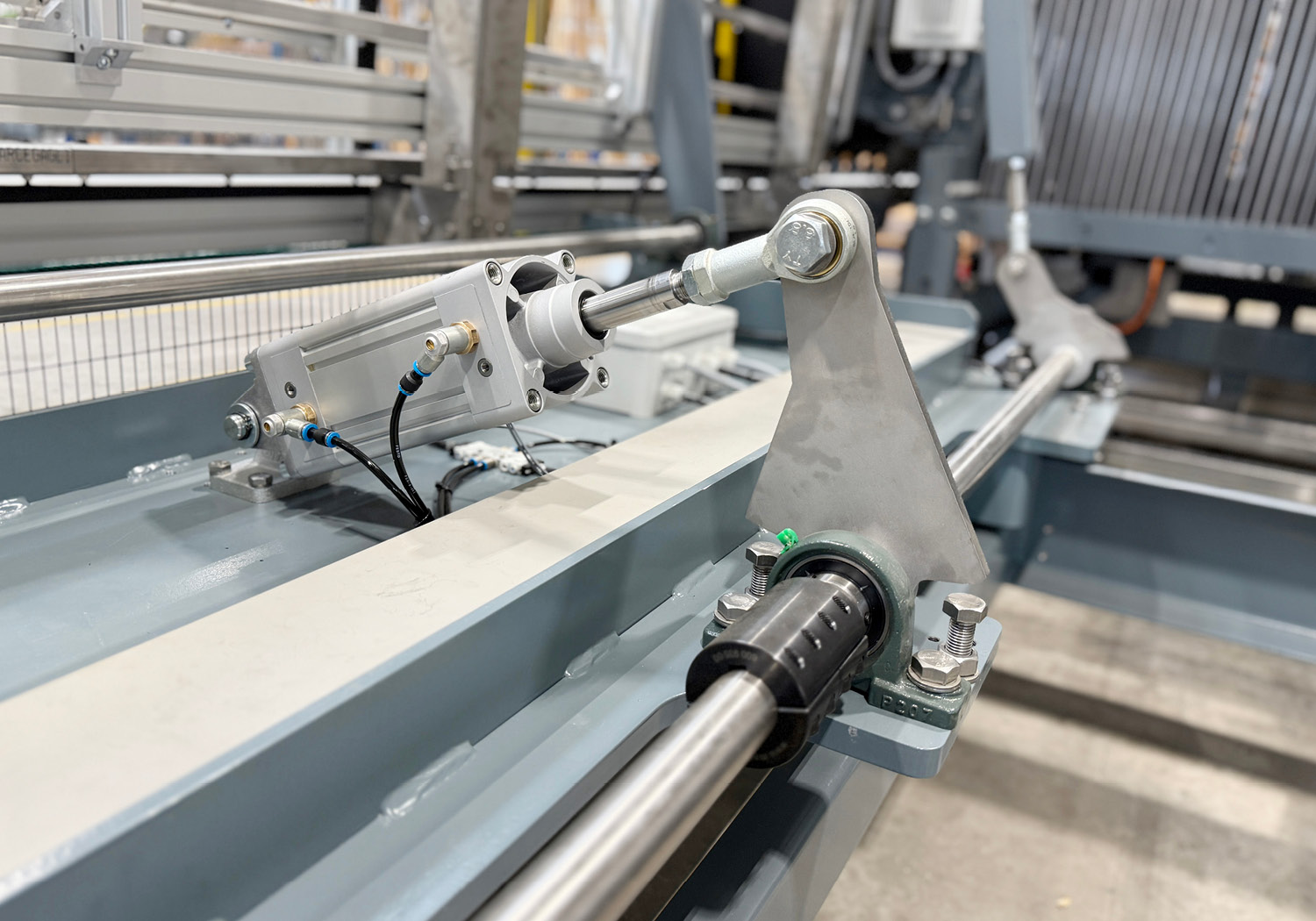

The system has been mechanically redesigned and improved in several key areas.

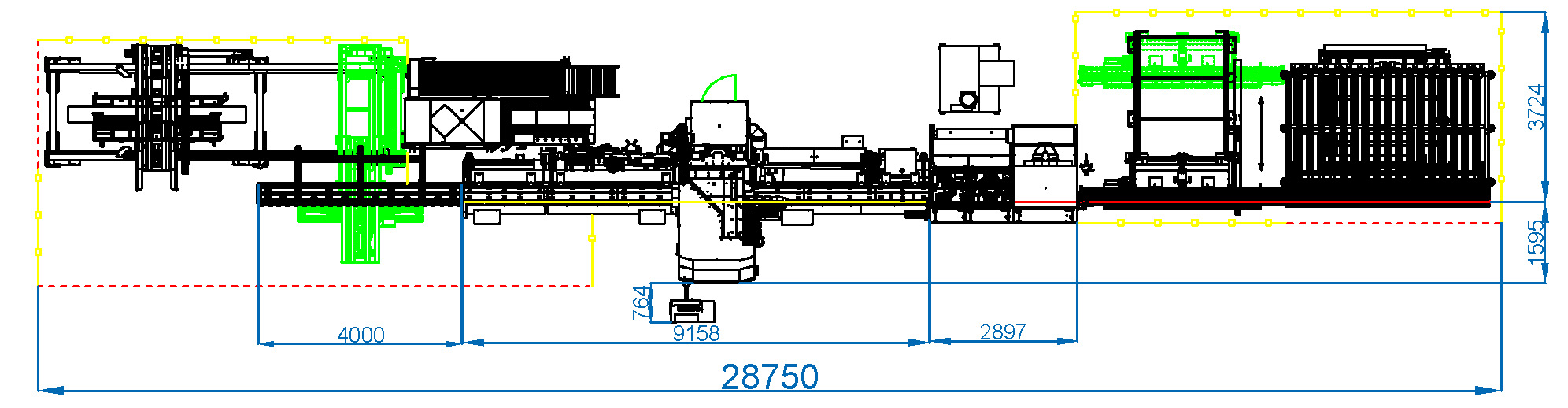

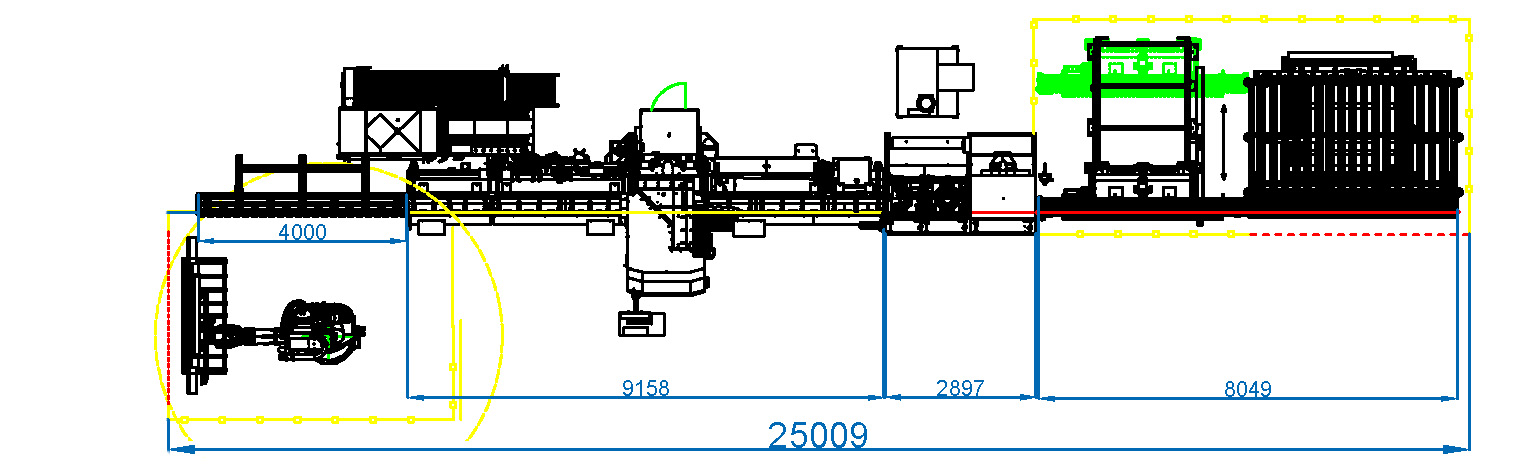

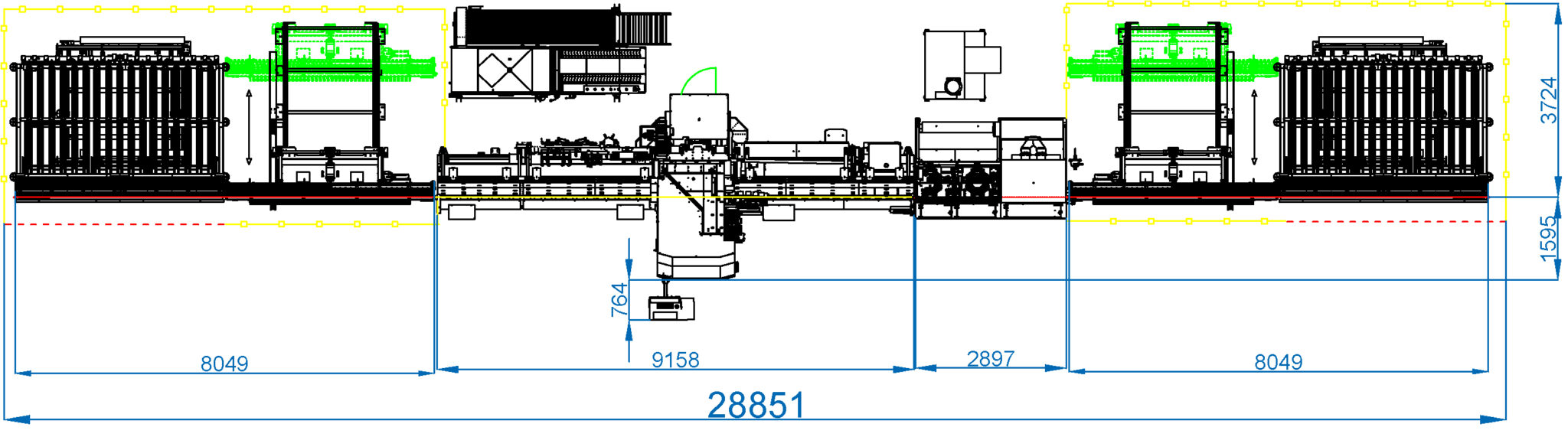

In addition to the newly integrated sorting function, the storage now offers higher capacity, supports multiple loading operations, and can handle larger glass formats – up to 3750 × 2000 mm instead of the previous 3000 × 2000 mm.

At the same time, the overall length of the installation has been reduced, making it easier to integrate into existing production environments.

Thanks to its modular design, the capacity can be expanded flexibly – it can be doubled or even tripled if required. This provides greater autonomy for fully automatic operation and minimizes downtime across the entire glass production line.

On the outfeed side, the integrated sorting function automatically assigns glass sheets according to freely definable criteria – such as thickness, size, job number, or next processing step.

The goal: to reduce internal transport trolleys, shorten transport paths, and free up valuable production space.

“We wanted to provide our customers with a solution that not only buffers but actively organizes,” explains Thomas Haan, Head of Sales at systron.

“With higher capacity and the ability to handle larger formats, production becomes even more autonomous. The new sorting function helps minimize internal transport processes and optimize available space – reducing working time per product and significantly increasing competitiveness.”

In addition to these innovations, the storage continues to impress with its compact design and modular scalability, ensuring maximum flexibility for any production concept.