“As for Vetrotech Poland, an expansion of the Namyslow plant is planned for the first quarter of 2024,” explains Vetreotech project manager. The additional office space will serve as an administrative centre.

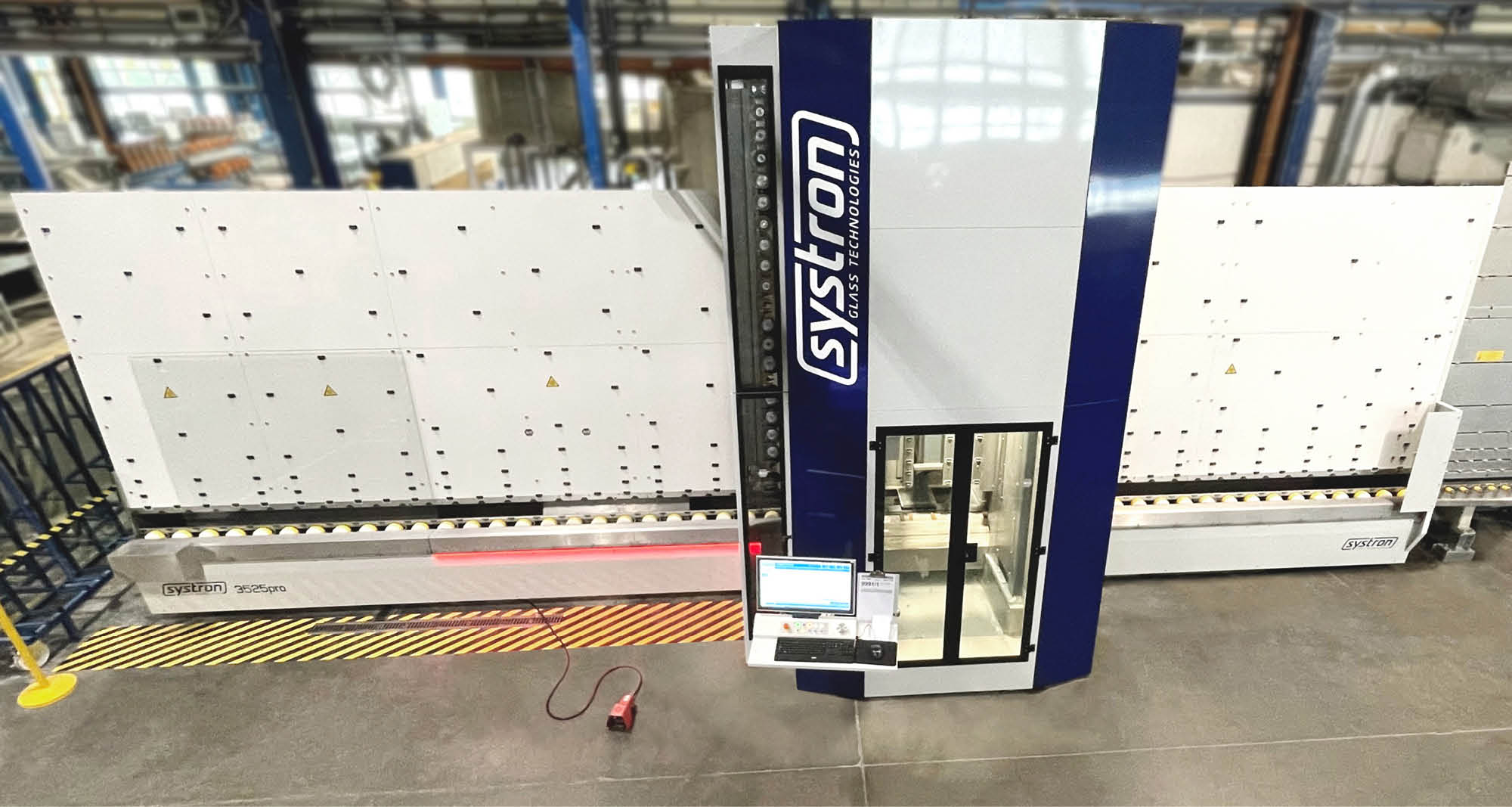

Miroslaw Kwiatkowski, country manager responsible for systron’s operations in Poland, adds: “Although systron machines have already been appreciated by companies from 17 countries: from Austria, Germany, Switzerland, the Netherlands, Belgium, Great Britain, the Czech Republic, Hungary, Finland, Sweden, Norway, Denmark, Russia, Estonia and, of course, Poland, and recently also from Italy and Turkey, we are always extremely pleased to see another installation in Poland, on one of the most important and, after all, largest glass markets in Europe. We are convinced that the intensification of processes related to the automation of production, the reduction of labor costs and the growing demands of the markets to improve quality and efficiency provide us with excellent opportunities for development.”