Jumbo Glass Meets High-Tech Precision – Eckelt Relies on the systron 9333proHD

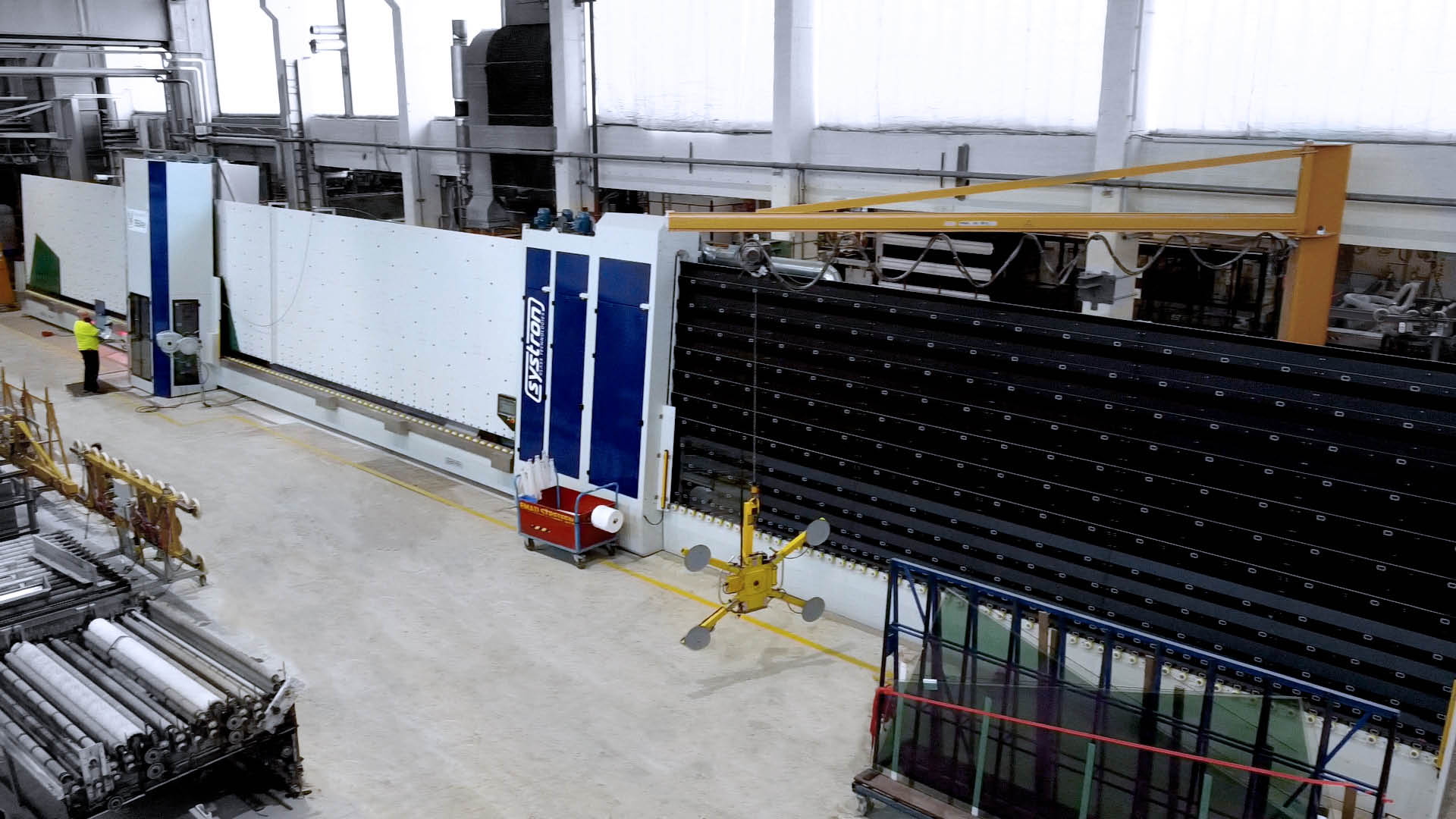

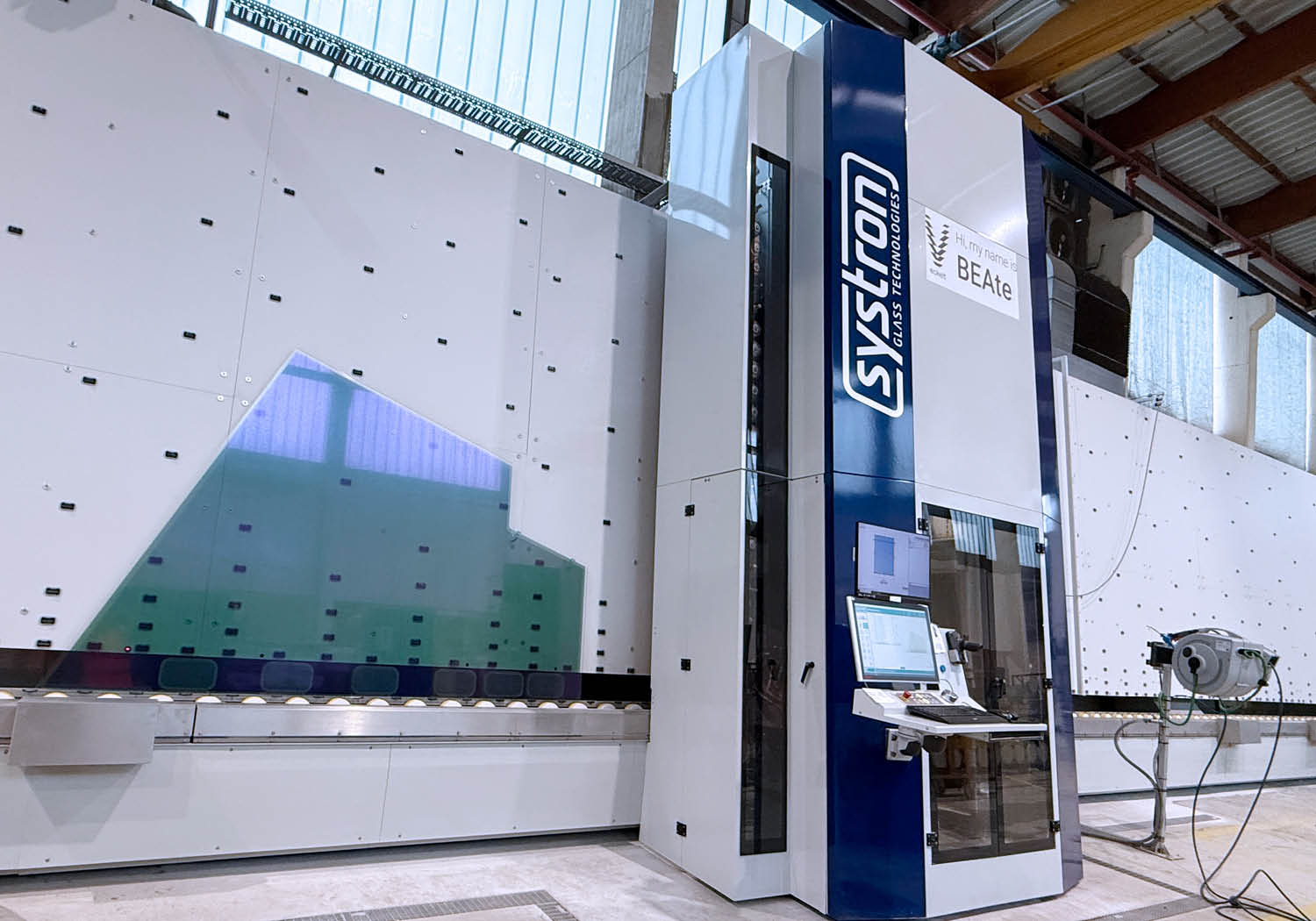

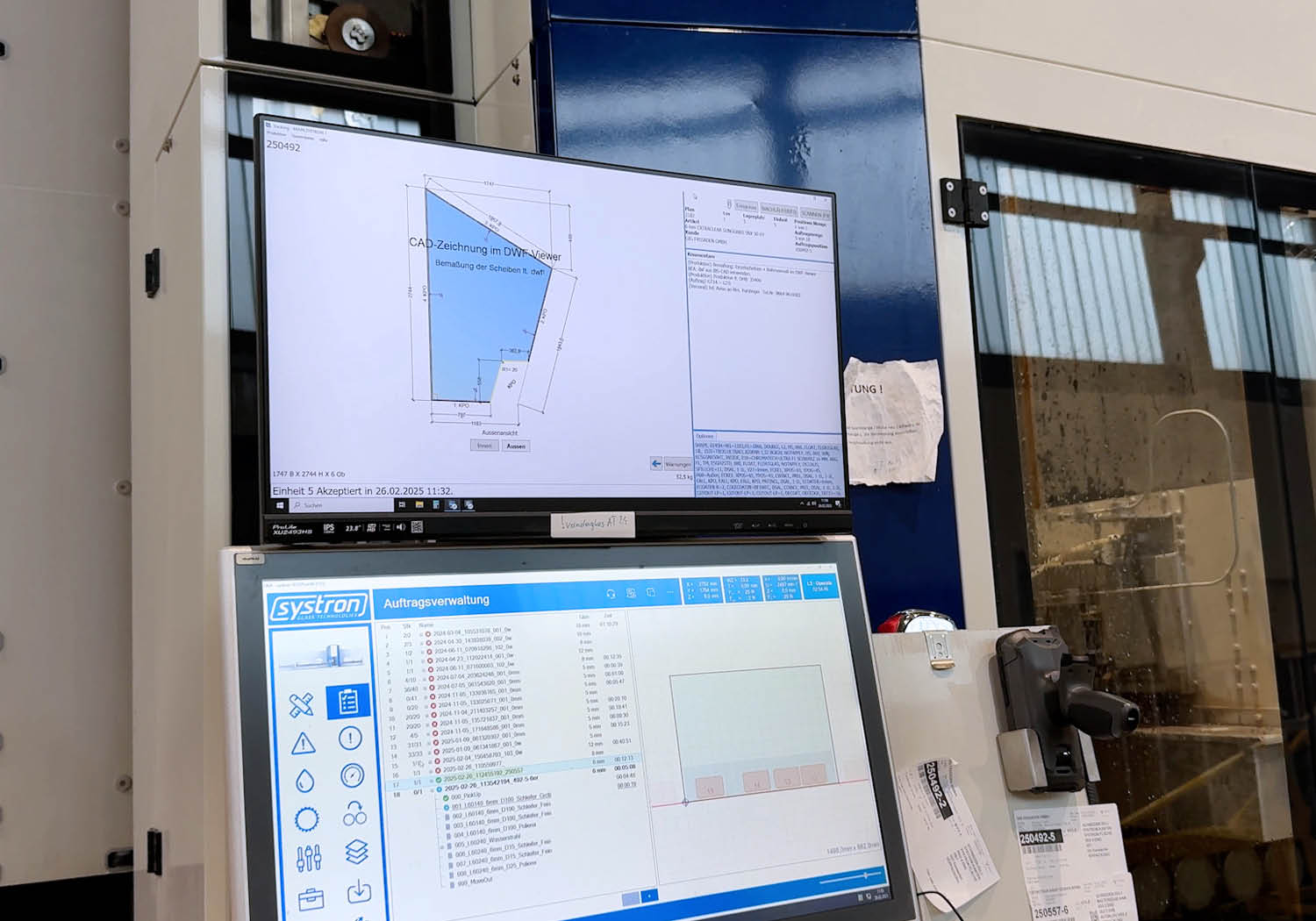

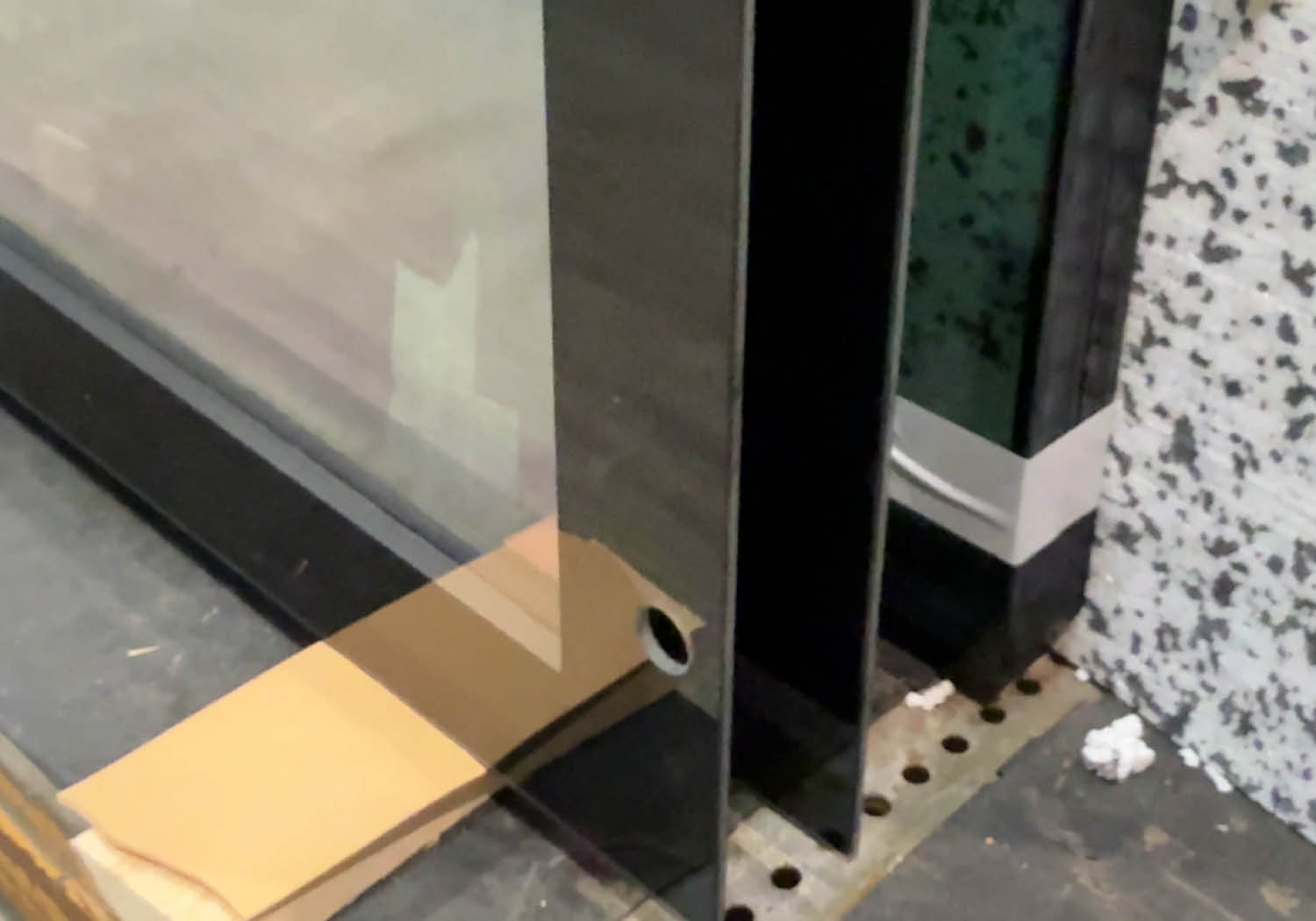

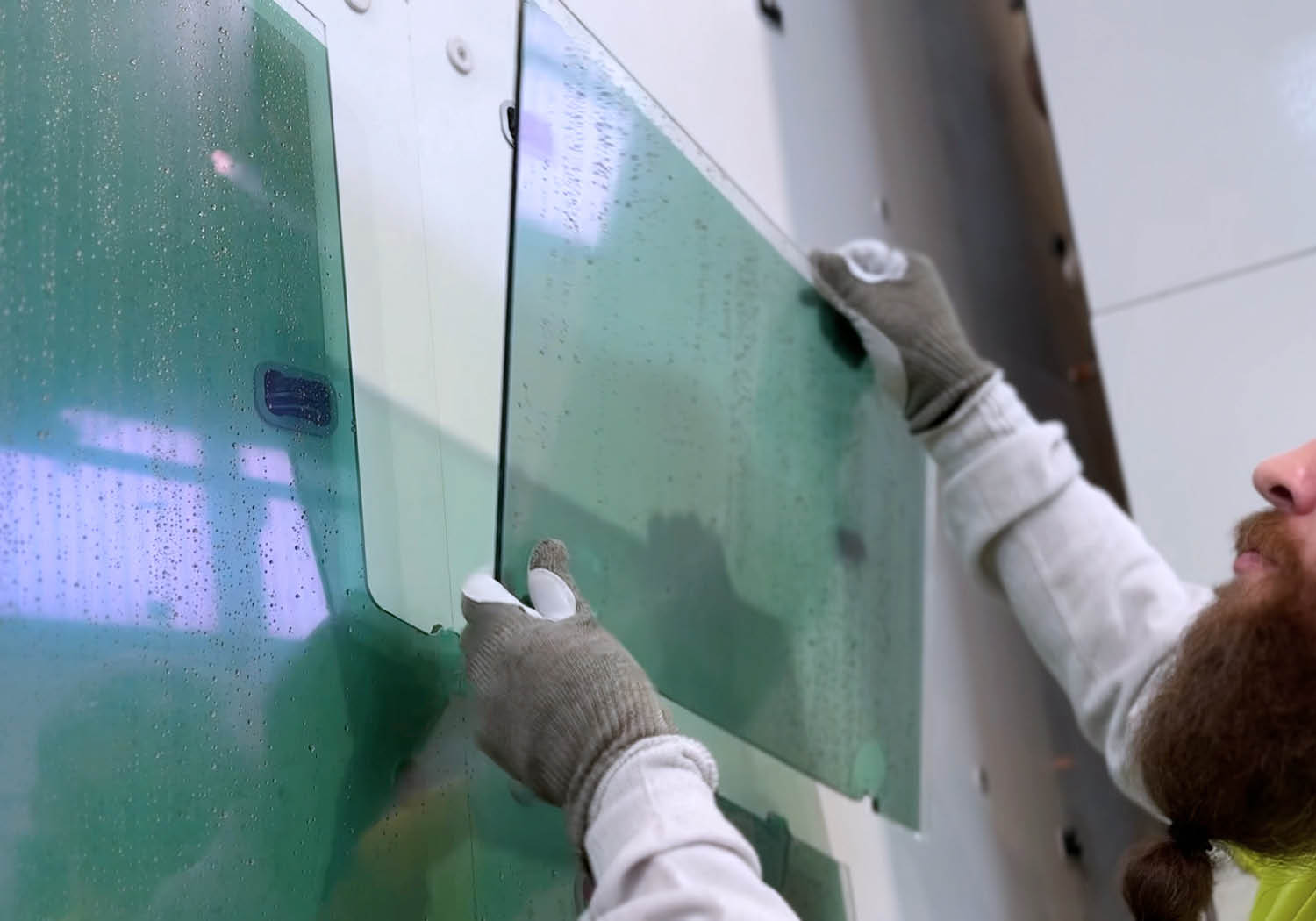

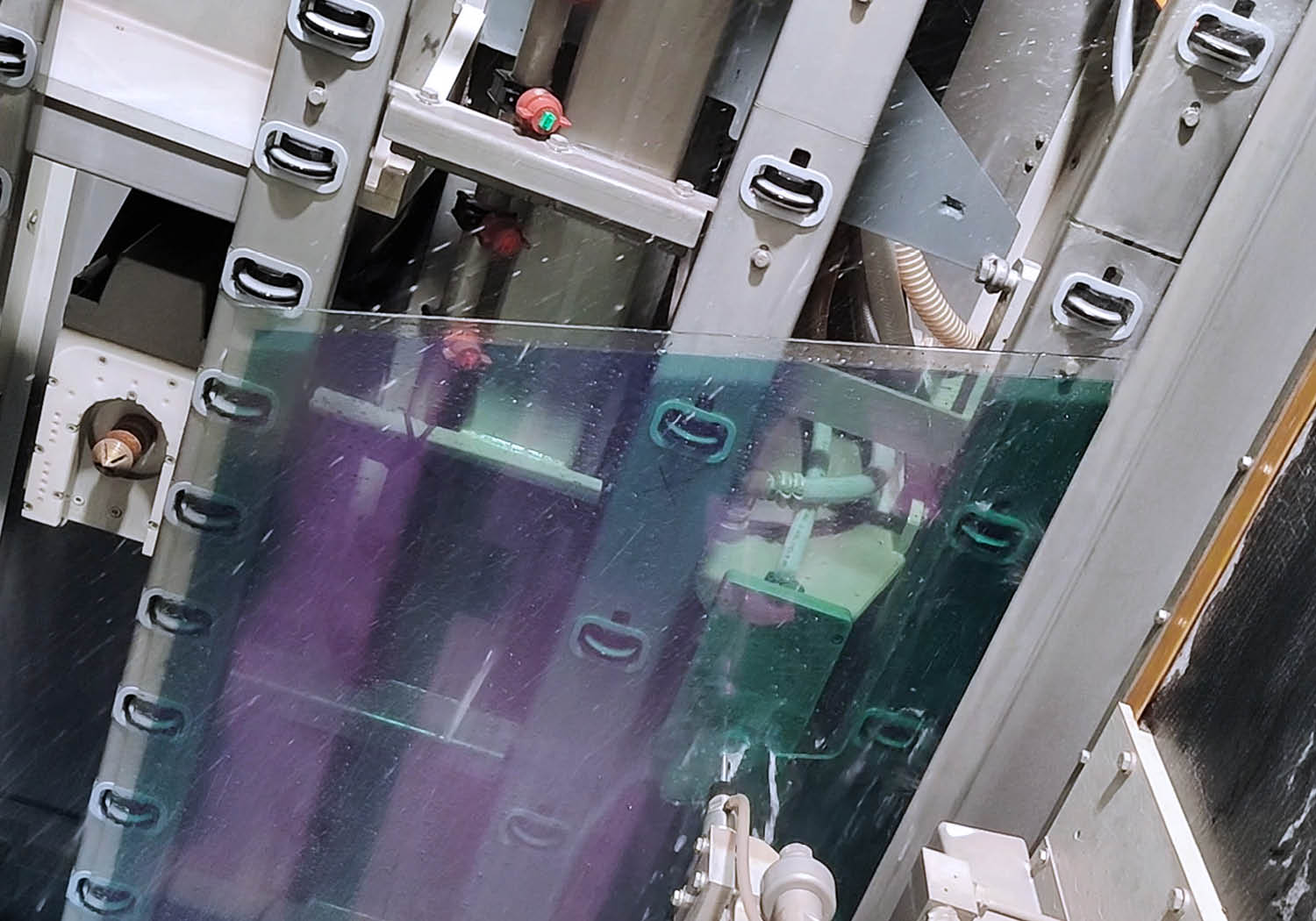

At vandaglas Eckelt GmbH, one of the world’s leading architectural glass refiners, precision is not just a goal – it’s a lived reality. With more than 100 years of experience, the company based in Steyr, Austria, stands for tailor-made architectural glass solutions in XL dimensions, manufactured to the highest quality standards. In January 2024, Eckelt took another major step toward the future by integrating the state-of-the-art systron 9333proHD glass processing centre, complete with a washing & drying unit and inspection zone.