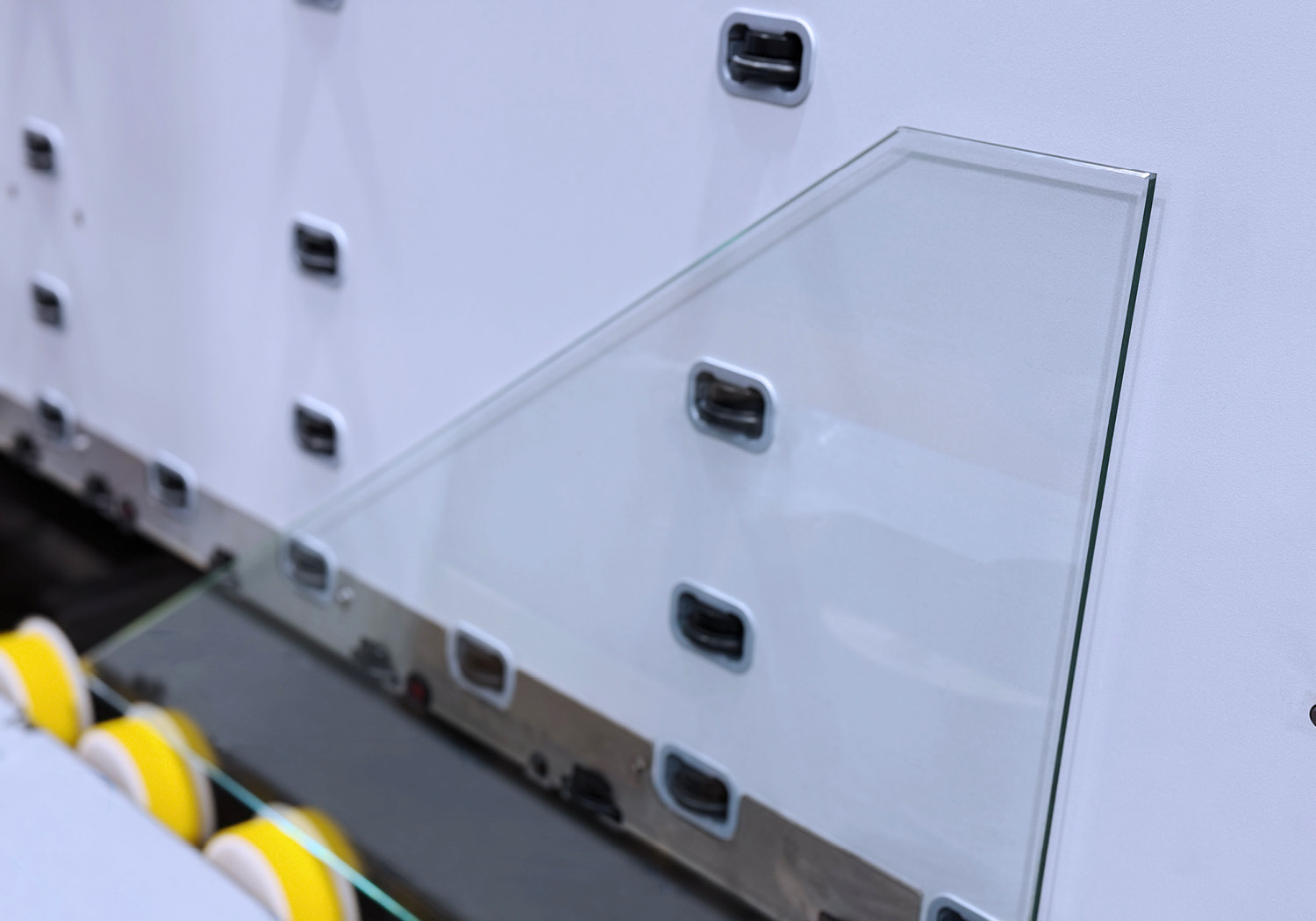

A key highlight of the systron pro is its user-friendly operation. With Easy Mode, processing rectangular glass can be automated with just one click. The machine uses a predefined recipe that specifies edge processing, material removal, as well as sharp or rounded corners. Additionally, thickness, length, and height are automatically measured, a DXF file is created, and the glass is processed precisely according to the specifications.

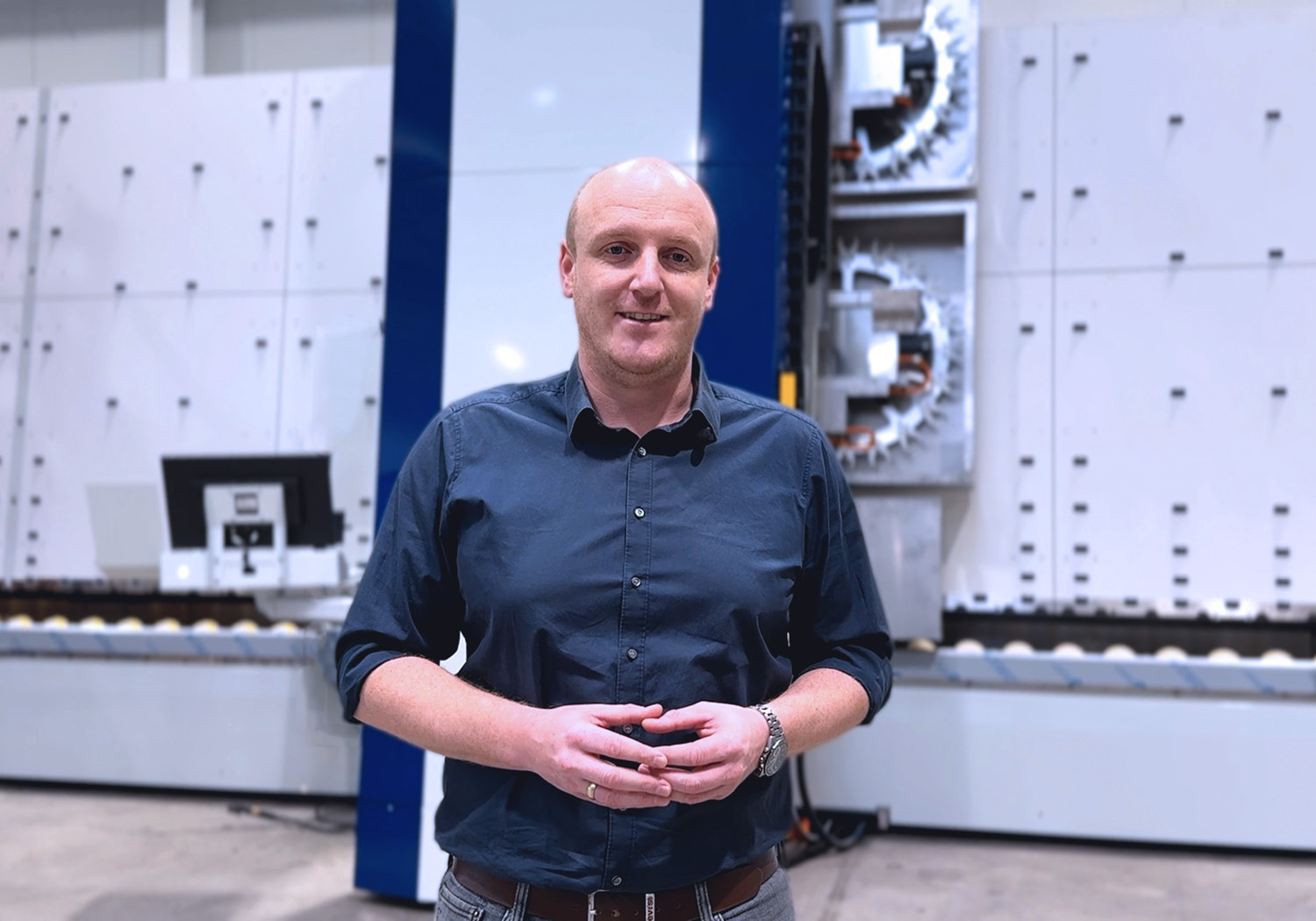

“Our machine has been designed to be efficiently operated even by less experienced users. This minimizes training requirements while increasing process reliability,”

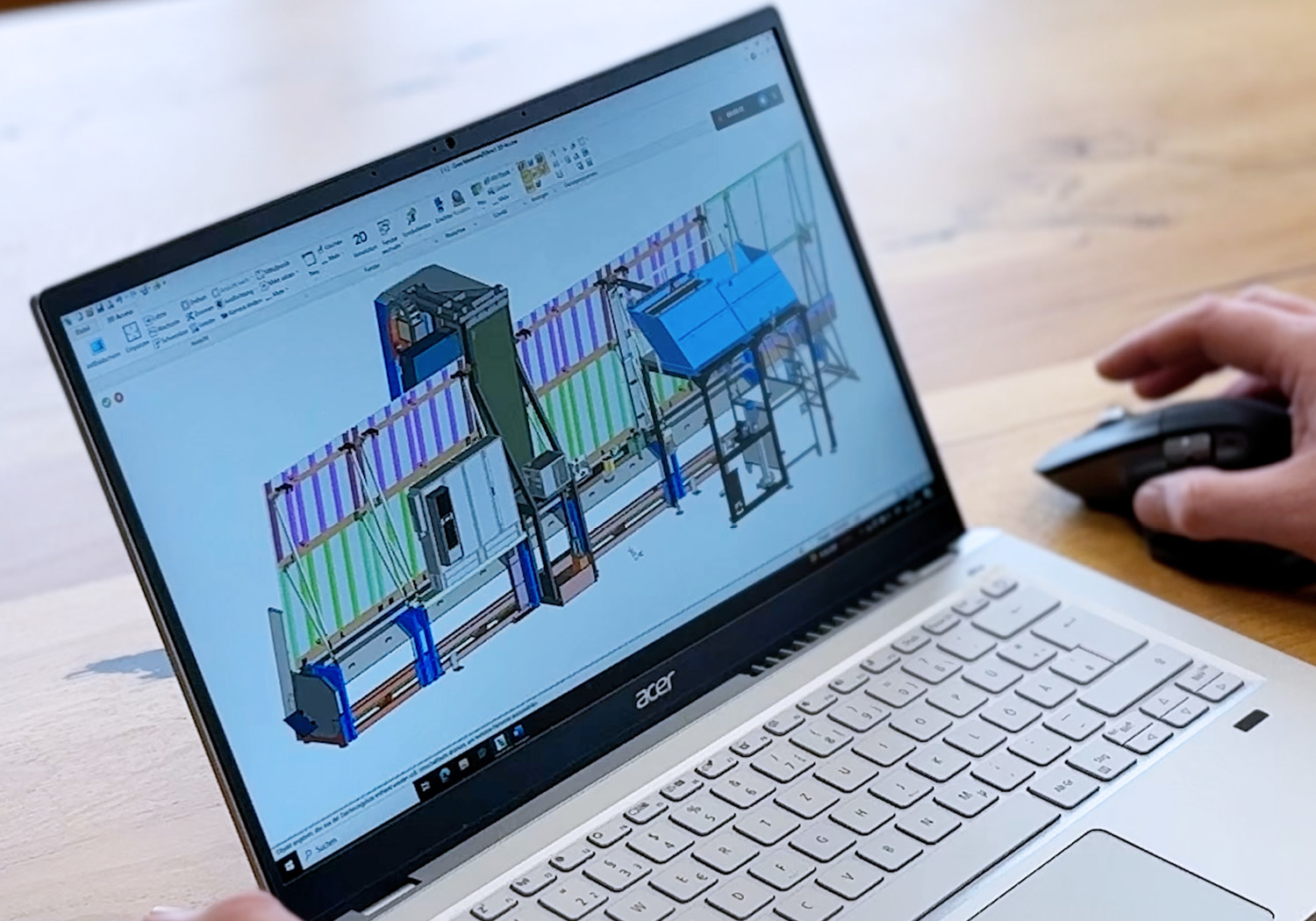

explains Andreas Gruber, Head of Product Development at systron. He adds: “The next generation of systron pro will also feature a drilling function. Using the Helix process, holes ranging from approximately 6 to 30 mm in diameter can be drilled into the glass. The combination of edge processing and drilling in a single machine tower significantly reduces processing times.”

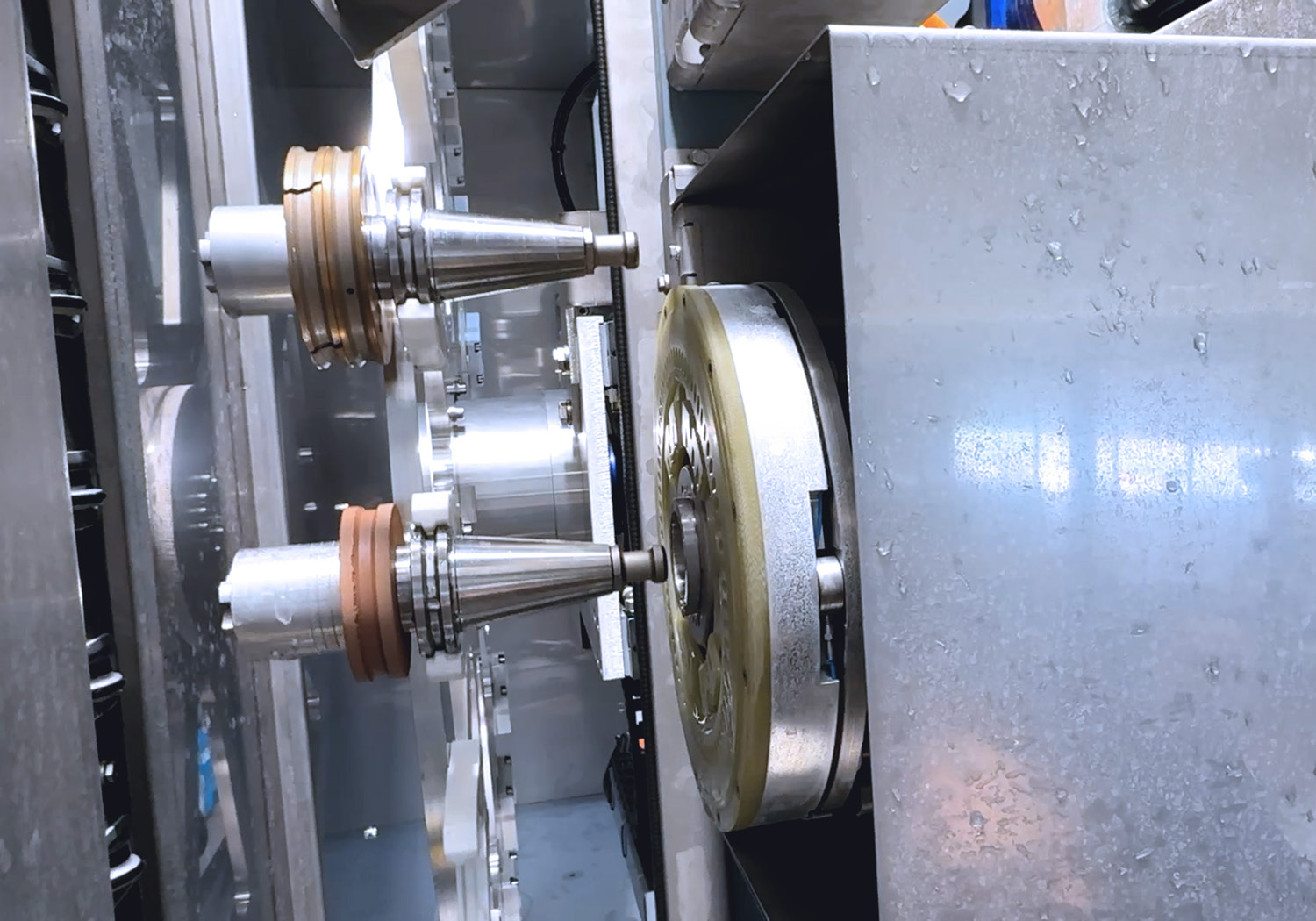

Maintenance and service have also been prioritized: All key components, such as the tool changer, motors, linear guides, and clamping boxes, are housed in a protected dry area.

“The design has been deliberately optimized to ensure that maintenance tasks require minimal effort—because only an easy-to-maintain machine will actually be maintained consistently,” says Thomas Haan, Head of Sales at systron.