Founded in 1962, Lasiliiri is a prominent player in the Finnish glass manufacturing industry. Based in Riihimäki, the company has a turnover of approximately 10 million euros and employs 40 dedicated staff members. Specializing in the production of construction glass, Lasiliiri is known for its wide range of products, including insulated glass (IG), laminated glass, toughened glass, and fire-resistant glass. Annually, the company processes around 400,000 m² of glass.

Lasiliiri serves a diverse clientele, including window and door manufacturers, steel constructors, balcony and terrace manufacturers, indoor wall constructors, and various industrial customers.

Investment in Innovation: systron 3525proHD + Washing Machine

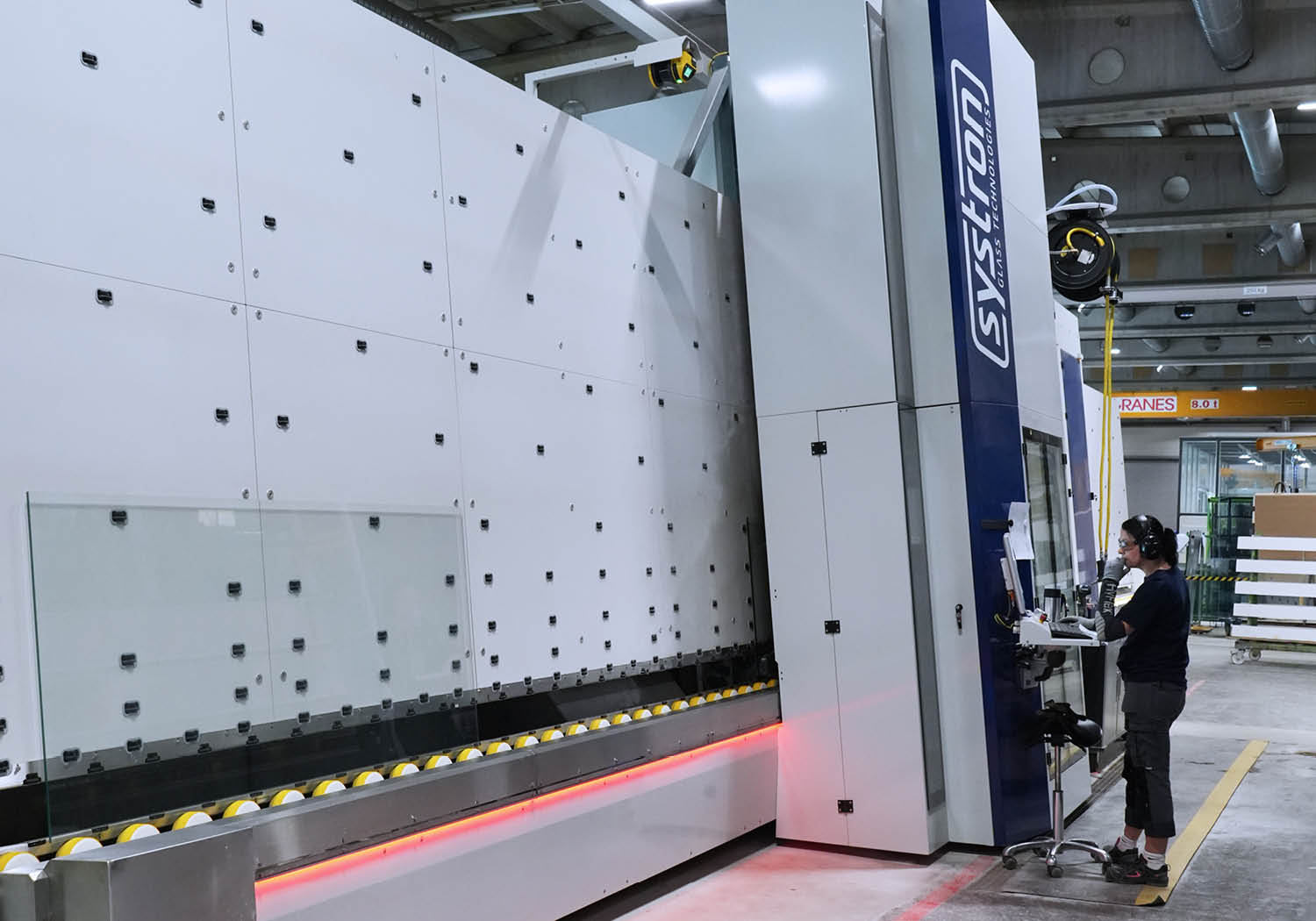

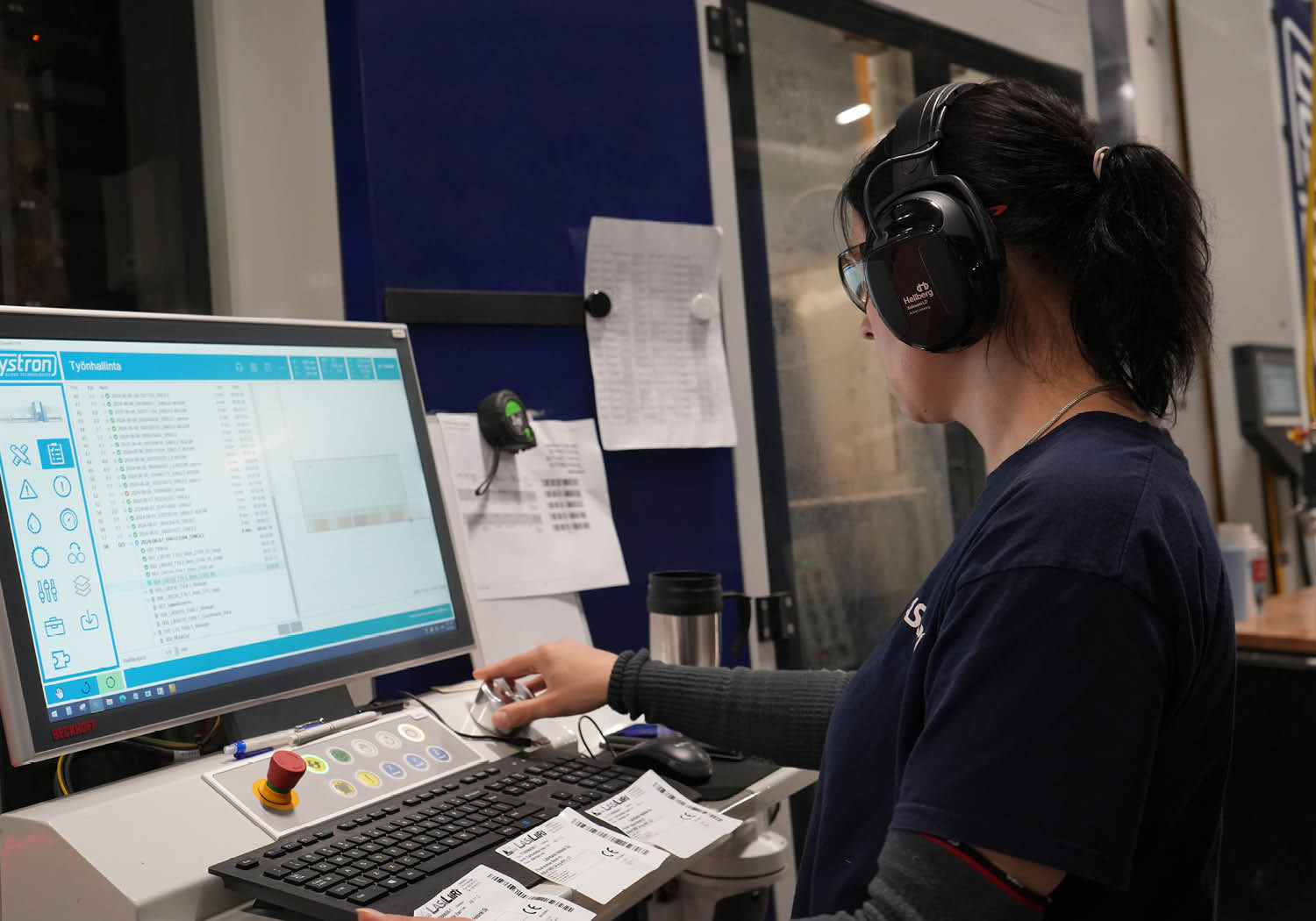

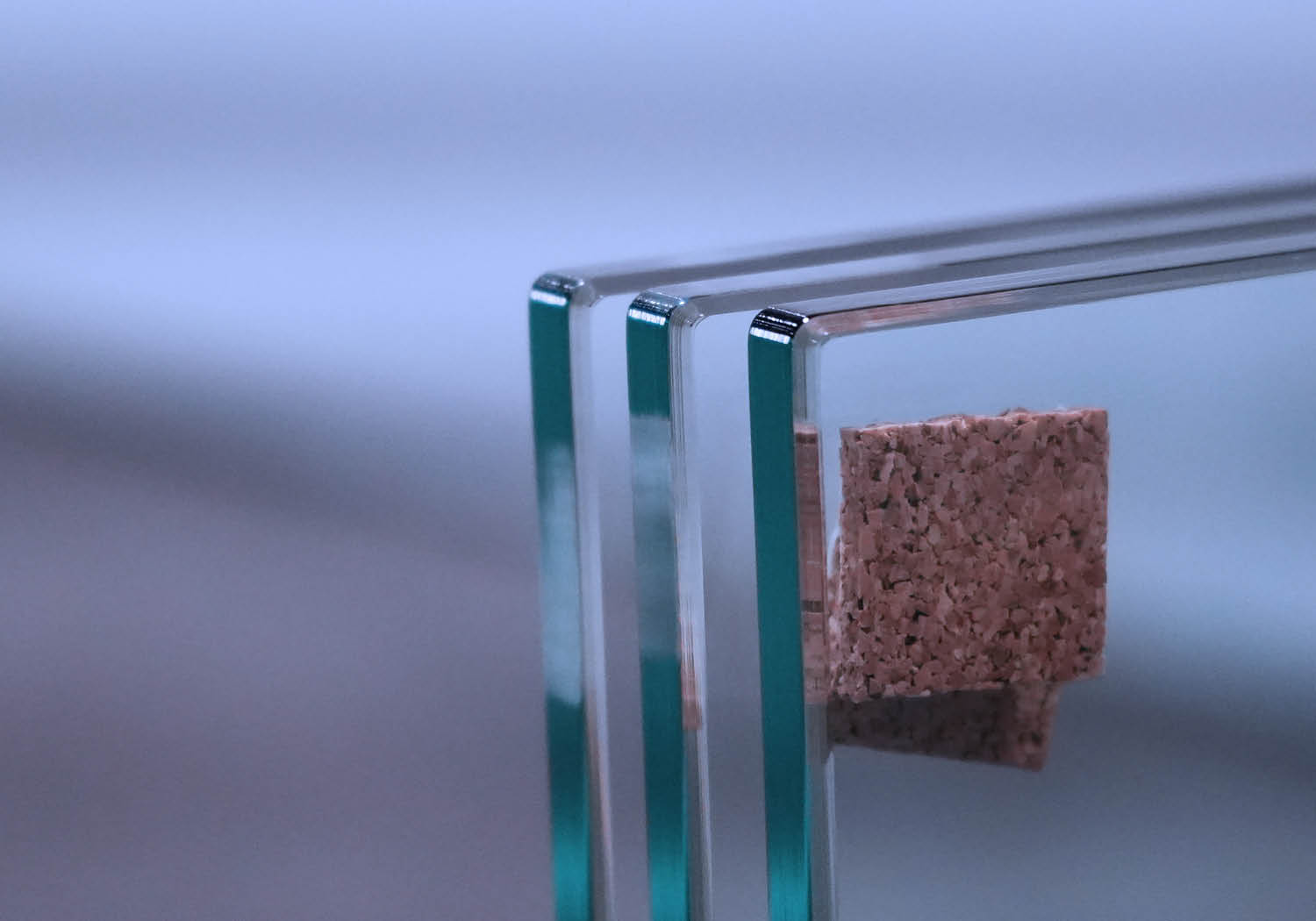

In July 2023, Lasiliiri Oy installed the systron 3525proHD, a CNC glass processing machine with cutting-edge waterjet cutting technology, to enhance their production capabilities. Anu Talja, Owner, Financial and Production Manager, provides insights into the decision-making process and the performance of the new equipment: “Our primary requirements for the new machine were high capacity, exact CNC cutouts and top-quality. The proHD turned out to be the perfect match for our requirements. Especially the waterjet feature was a major factor in our choice, along with the comprehensive package offered at a competitive price.

The enormously precise waterjet cut is essential for laminated glasses.”

Various Applications and top Performance

The systron 3525proHD is mainly used for processing laminated glasses, particularly for models with cutouts. The average throughput varies significantly based on the type of glass and the specifics of each order, changing from week to week. The machine operates 2-3 shifts, five days a week, ensuring continuous and efficient production. After 10 months of operation, Lasiliiri is pleased with their decision to invest in the CNC waterjet centre. Anu Talja says: “The machine has performed well, managing all assigned tasks without significant issues. This machine is our first with a waterjet feature and we definitely can recommend this fast and flexible way of cutting glass. Moreover the after-sales service from systron has been commendable. Responses are quick, and the competence of the systron team is impressive. The system availability has been tracked and is very satisfactory.

Our expected return on investment of 5 years is on target and the calculated service life of the machine is 15 years.”

Automated Loading and Future Prospects

Lasiliiri has recently installed automated loading to further enhance their cutting line and use the same racks, which is beneficial for serial production and reduces the handling of glass. Plans include possibly purchasing an automatic systron storage or robot solution to streamline operations even more. They believe that this enhancement will make them more competitive through higher automation, and they expect to quantify the efficiency gains over time.

Lasiliiri’s investment in the systron 3525proHD + WM underscores their commitment to innovation and quality in glass processing. With continuous improvements and a focus on automation, Lasiliiri Oy is well-positioned to maintain its competitive edge in the industry.